Product descriptionThe main material of glass fiber clutch facing is a composite cloth made of ordinary medium-alkali (alkali-free) glass fiber yarn, blended fiber and one or two 0.17 copper wires. The materials are imported styrene-butadiene rubber 1502, high decomposition temperature phenolic resin and modified phenolic resin, friction performance improver. This range of products follows the traditional rubber impregnation technique.

Contact Now

Product descriptionThe main materials of this product are ordinary medium-alkali (alkali-free) glass fiber yarn, various glass fiber cloths that meet customer needs processed through certain processes, imported styrene-butadiene rubber 1502, ordinary modified phenolic resin, and friction performance regulator Composed of other materials, this product is produced using the traditional rubber impregnation process and is suitable for complex roads such as mountains and deserts. Packaging and shippingIn order to better protect the safety of your goods, we will provide professional, envi

Contact Now

Product descriptionWhen the clutch is engaged, power can be transmitted from the engine to the transmission and drive wheels. Clutch facings ensure the gears don't grind against each other in the process and provide resilience and support. Due to the pressures within the engine and the often extreme conditions, especially at constant high speeds, the finish will inevitably wear.

Contact Now

Product descriptionThe main material of High Copper Clutch Facing LH8106 is composite cloth made of ordinary medium alkali (non-alkali) glass fiber mixed fiber and 4-7 0.19 copper wire, imported styrene butadiene rubber 1502, high decomposition temperature phenolic resin, friction performance regulator, etc.

Contact Now

Product descriptionThis enables the engine and transmission to gradually engage, thereby ensuring a smooth start of the car. Temporarily disconnects the engine from the transmission to facilitate shifting and reduce shift shock.

Contact Now

Product descriptionCarbon fiber clutch facing refers to clutch facings that are made primarily or entirely from carbon fiber materials. Carbon fiber clutch facings are commonly used in high-performance applications, such as racing cars, sports vehicles, and heavy-duty industrial machinery. However, they may come with a higher price tag compared to other types of clutch facings.

Contact Now

Product descriptionWhen the car is under emergency braking, it can act as a separation to prevent transmission systems such as transmissions from being overloaded, thus playing a certain protective role. The clutch is composed of friction plates, spring plates, pressure plates and power output shafts. It is located between the engine and the gearbox. It is used to transfer the torque stored on the engine flywheel to the gearbox to ensure that the vehicle is transferred to the gearbox under different driving conditions.

Contact Now

Product descriptionThe clutch is located in the flywheel housing between the engine and the gearbox. The clutch assembly is fixed on the rear plane of the flywheel with screws. The output shaft of the clutch is the input shaft of the gearbox. While the car is driving, the driver can depress or release the clutch pedal as needed to temporarily separate and gradually connect the engine and the transmission to cut off or transmit the power input from the engine to the transmission.

Contact Now

Product descriptionDepending on the application, clutch facings can be made from a variety of materials, but some of the most common include asbestos, textile fabrics such as Kevlar and Kevlar, and ceramic materials. Like disc brake pads and other clutch materials, the materials used for clutch facings need to be durable. Because the process of driveshaft engagement and disengagement involves the conversion of kinetic energy to thermal energy, the clutch facings must be able to withstand the tension and high temperatures reached during this process.

Contact Now

Product descriptionWhen the clutch is closed, power can be transferred from the engine to the transmission and drive wheels. Clutch linings ensure that the gears do not rub against each other during this process and provide flexibility and support. Due to the pressures and extreme conditions that often occur in engines, especially at constant high speeds, wear and tear on surfaces inevitably occurs.

Contact Now

Product descriptionClutch friction plates mainly use asbestos-based friction materials. As the requirements for environmental protection and safety become higher and higher, semi-metallic friction materials, composite fiber friction materials, and ceramic fiber friction materials gradually appear. Compared with clutches made of other materials, ceramic clutches perform better in terms of overload capacity. The main reasons are as follows: 1. Different material strengths: Ceramics are a high-strength material. In comparison, asbestos has low strength and is prone to deformation and breakage.

Contact Now

Product descriptionThe new ceramic formula uses a variety of lightweight porous fillers and does not contain any metal components (steel fiber foam, iron powder, heavy metals, etc.). Compared with semi-metallic formulas, ceramic brake pads have larger porosity and lower density. At the same time, compared with resin-based friction materials, the hardness of ceramic-based friction materials is also lower.

Contact Now

Product descriptionWith good mechanical strength and physical properties, friction material products need to be drilled, riveted, assembled and other mechanical processing before being assembled and used to make a brake pad assembly or clutch assembly. During the friction work process, the friction material not only has to withstand high temperatures, but also withstands large pressure and shear forces. Therefore, friction materials are required to have mechanical strength to ensure that they will not be damaged or broken during processing or use.

Contact Now

Product DescriptionComposite yarn clutch faces are clutch faces made from composite yarn materials. Composite yarn clutch facings are generally considered more environmentally friendly than traditional asbestos clutch facings. It contains no harmful substances, has low toxicity and is safer to use and dispose of.

Contact Now

Product descriptionComposite yarn take hold of facings are grab facings that are made of composite yarn materials. Composite yarn grab facings are frequently regarded extra environmentally pleasant in contrast to typical asbestos-based grab facings. They do now not comprise hazardous substances and have low toxicity, making them safer to use and dispose of.

Contact Now

Product descriptionComposite yarn clutch facings are clutch facings that are made of composite yarn materials. Composite yarn clutch facings are often considered more environmentally friendly compared to traditional asbestos-based clutch facings.

Contact Now

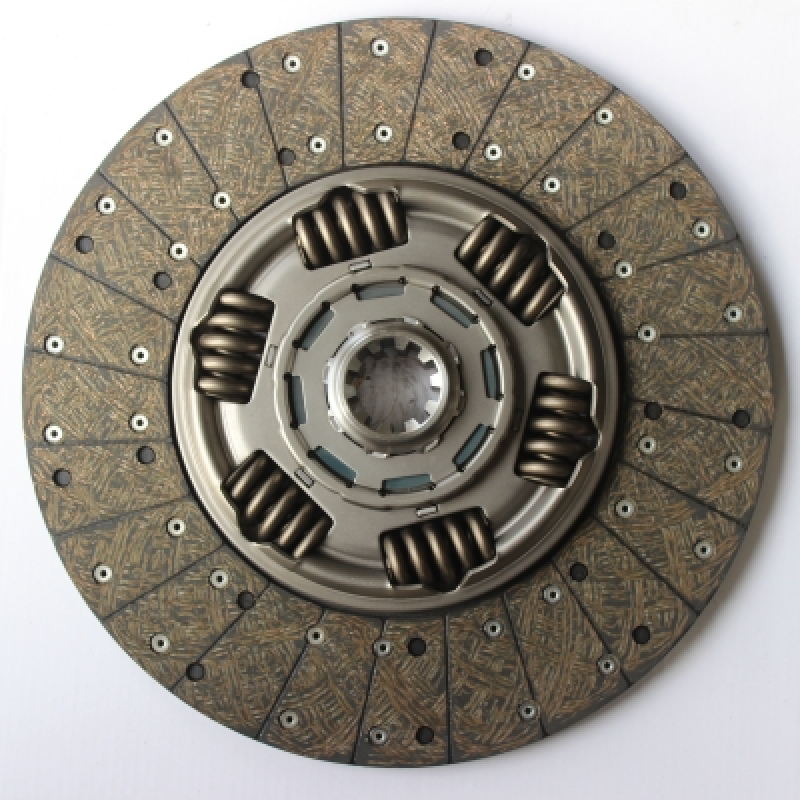

Product Description430 Clutch Disc For Mining Truck1.Common and high copper facing both avaliable,which suit for different market's demand.2.Long life,high quality steel,strong springs.3.We can develop new clutch as customer's samples or drawings. SpecificationApplicationwide body truckProduct NameClutch DiscWarranty12 MONTHSQualityHigh-Quality/100% Brand new and High qualityPlace ofOriginShandong,CHINAPackingCarton/ Neutral PackingSupply Ability1000 Set/Sets per MonthWeight15 kgSize430MM/OEM StandardMaterialIron and copperPackaging and shipping1.

Contact Now

Clutch and Pressure Plate for Mine Dump Truck Products DescriptionThe clutch cover can press the clutch driven disc onto the flywheel to transmit engine torque, and vice versa, control the rotation of the driven disc.The spring box pressing claw on the pressure plate is used to reduce the torsional rigidity of the head end of the transmission system, thereby reducing a certain order of natural frequency of the transmission system torsion systemThe friction clutch facing/linings on the clutch plate, just like the brake lining on the drum.

Contact Now

Product DescriptionThe clutch driven plate requires a certain amount of friction to ensure sufficient power transfer. At the same time, certain wear resistance and high temperature resistance are also required to ensure long-term reliability.The design and performance of the clutch driven plate directly affects the operating effectiveness and lifespan of the clutch, so when using or maintaining the clutch, it is necessary to pay attention to the degree of wear and friction of the clutch plate.

Contact Now

Product DescriptionThe clutch release bearing, also known as the release bearing, is an important part of the manual transmission system. Its main function is to engage and disengage the clutch by pressing the release finger on the clutch pressure plate.The clutch release bearing facilitates the engagement and separation of the clutch and plays an important role in the smooth operation of the clutch system. Regular inspection and maintenance of the release bearing will help prevent premature wear and ensure optimal performance of your manual transmission. Product advantages1.

Contact Now

Product descriptionA clutch is similar to a switch, engaging or disengaging power transmission. The active part and the driven part of the clutch mechanism can be temporarily separated, and can be gradually connected, and may also rotate relative to each other during the transmission process. There cannot be a rigid connection between the driving part and the driven part of the clutch.

Contact Now

Product descriptionThe clutch driven plate is a precision mechanical device that controls and regulates engine power. It is an integral part of the clutch. The clutch transmission plate is widely used in mechanical equipment such as automobiles and motorcycles.

Contact Now

Product DescriptionThe clutch is located in the flywheel housing between the engine and transmission. The clutch assembly is screwed to the rear of the flywheel. The output shaft of the clutch is the input shaft of the gearbox.

Contact Now

Product UsageThe clutch is mainly composed of four parts: the active part, the driven part, the pressing part and the operating mechanism. The clutch plate we usually call belongs to the driven part. Its working principle is also very simple, which relies on the principle of friction to transmit engine power.

Contact Now