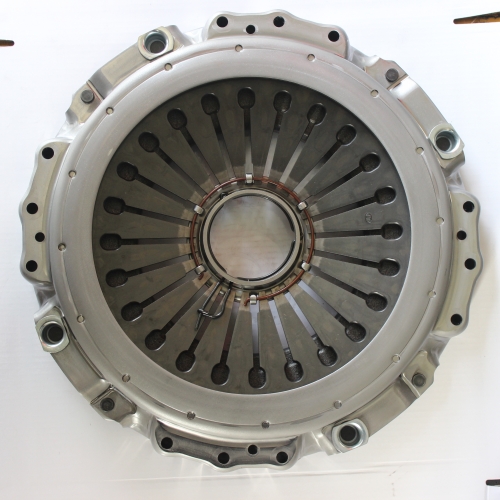

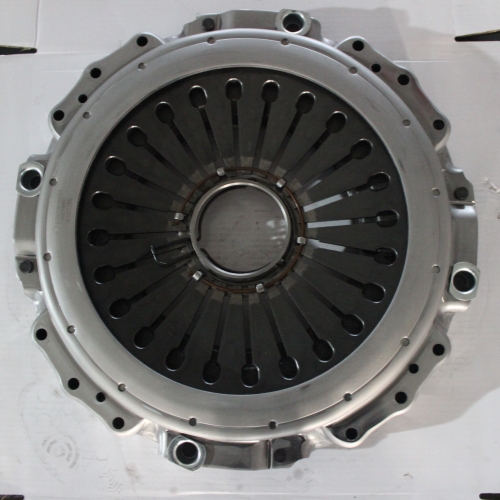

XCMG Mining Dump Truck Clutch Pressure Plate

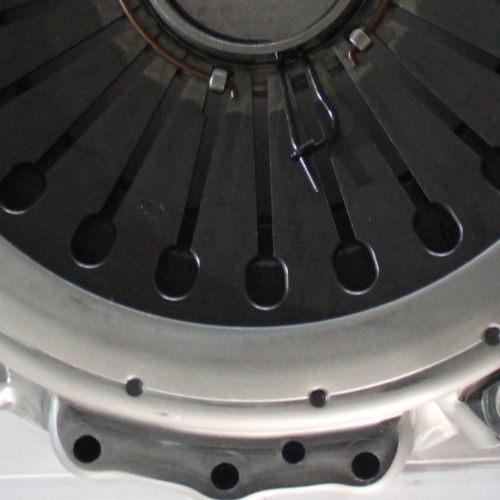

Highlight 1: Using 7mm cold-rolled plate, the look is neat and the thickness of the cloth ensures that the cowl does now not deform beneath excessive pressure.

Highlight 2: Diaphragm rock spring is made of 50CrV4 high-elastic spring steel, the fabric is appropriate for high-horsepower models, and it produces robust torsion transmission and steady excessive stress after expert warmness treatment.

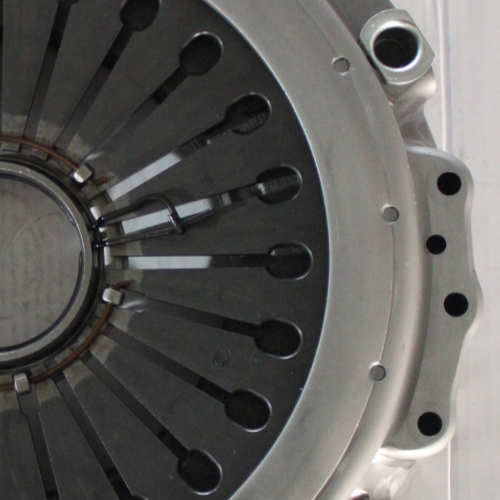

Highlight 3: The backside of the plate is made of HT250 solid iron, which is greater appropriate for friction and torque transmission due to its hardness and tensile strength. The weight utterly meets the warmness ability and inertia requirements, lowering ablation and frustration.

Highlight 4: The transmission plate is stamped and fashioned from particularly elastic 65Mn metal strips. The warmness remedy and tempering have small attenuation to make sure whole separation throughout use.

Highlight 5: Separate pull ring stamping forming, carbonitriding ensures tensile durability and put on resistance.

Highlight 6: The restrict snap ring reduces the chance of failure brought about by way of bumping and deformation all through transportation, and additionally enables installation.

Product description

A pressure plate of each clutch, actuated by a corresponding diaphragm, serves to hold the friction disk against a corresponding reaction disk. A reaction disk can be provided for each clutch. In a variant, a single reaction disk common to both clutches is used, which is mounted between the two friction disks.

Each friction disc rotates with an input shaft of the transmission, and each reaction disc rotates with a flywheel connected to the drive shaft. The friction discs are therefore pressed between the corresponding pressure and reaction discs and can transmit torque between the drive shaft and the associated transmission shaft.

The use of a clutch causes friction lining wear of the friction plate and associated wear of the opposing materials of the pressure plate and reaction plate. This manifests itself as a change in the position of each pressure plate relative to the diaphragm and/or associated reaction plate, resulting in a change in the pressing force of the friction disc and/or a change in the stroke and engagement point of the clutch release bearing. As a reminder, the bite point is the position from which part of the engine torque is transmitted to the transmission shaft when the clutch is closed.

Company strength

Lihong Holding Group Co., Ltd. is a manufacturer of clutch plates, clutches, clutch covers, clutch pressure plates, and clutch plates. Its products have passed ISO/TS16949 quality system certification. The products are not only matched with well-known domestic automobile manufacturers, but also exported to Europe and the United States. , the Middle East and Southeast Asia and other more than 20 countries and regions.

Packaging and shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.