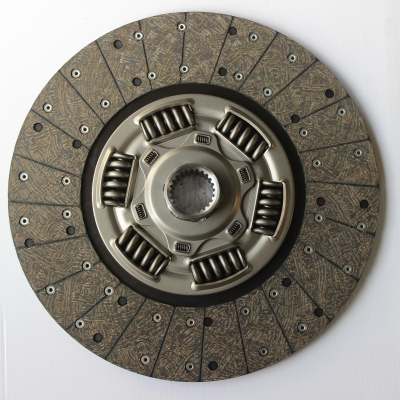

Clutch Disc For Car

Carbon fiber clutch facings have several unique characteristics and advantages:

1. High strength and lightweight: Carbon fiber is known for its exceptional strength-to-weight ratio. Clutch facings made from carbon fiber are significantly lighter than traditional materials such as asbestos or paper-based facings, while still offering high strength and durability.

2. Excellent heat resistance: Carbon fiber clutch facings can withstand high temperatures without degrading, making them suitable for high-performance applications. They have good thermal stability, ensuring consistent and reliable performance under demanding operating conditions.

3. Low wear rate: Carbon fiber has inherent wear resistance, resulting in lower wear rates compared to other materials. This translates to a longer service life for the clutch facing, reducing the need for frequent replacements and maintenance.

Product description

The clutch disc is an essential component of a car's clutch system. It is located between the engine flywheel and the gearbox input shaft. When the clutch pedal is engaged, the clutch disc transfers the engine's rotational power to the transmission, allowing for smooth gear changes and the proper transmission of power.

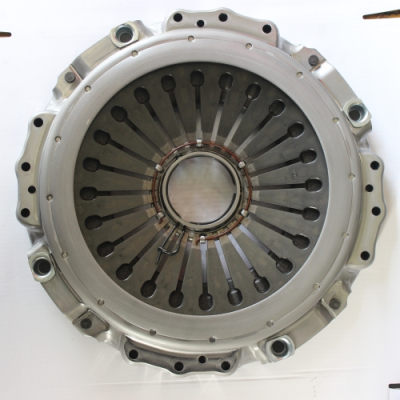

When replacing a clutch disc, it is often recommended to replace the entire clutch assembly, including the pressure plate and release bearing, for a complete and balanced system.It is essential to consult the car's manufacturer specifications or seek professional advice to ensure the correct selection and installation of a clutch disc for a particular car model and driving needs.

Product parameters

Product Properties | |||

OENO. | 1601210-76A, 1601210-76B | Product Name | Clutch Disc |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | MOQ | 10pcs |

Size | 430MM/OEM Standard | Weight | 15 kg |

Type | Clutch Disc/Clutch Assembly | Payment | T/T |

Brand Name | LH | Material | Iron and copper |

Condition | New | Delivery time | 7-15days |

Color | As shown | Shipping | DHL UPS EMS FEDEX |

Port | Qingdao port | Certification | TS16949 |

Truck Model | XCMG,LCMG,SDLG,SANY,LiuGong, TONLY,CNHTC | ||

Packaging and shipping

The manufacturing process of a clutch disc

1. Design and planning: According to the requirements and specifications of the clutch system, formulate the design and planning scheme of the driven disc. This includes determining elements such as material, size and geometry.

2. Material preparation: choose the appropriate material for making the driven disc. Common materials include steel, cast iron, and aluminum alloys. Depending on the need, material processing such as cutting, forming or casting may be required.

3. Manufacture and molding: According to the design plan, use appropriate technology and equipment to manufacture the driven disc. This can include milling, turning, stamping and more to transform the raw material into the final driven disc shape.

4. Surface Treatment: Provide the necessary surface treatment to the driven disc to provide the desired friction characteristics and wear resistance. This can include processes such as heat treatment, grinding, plating or coating.

5. Functional testing: Functional testing of manufactured driven discs to ensure that they meet specified requirements and performance. Testing typically covers aspects such as friction performance, load carrying capacity and durability.

6. Packaging and delivery: Packaging and labeling of the tested driven disc to ensure its safe transportation and delivery to the end user or manufacturer. According to requirements, additional identification, instructions or quality inspection reports may be required.

The process of making a clutch driven disc requires strict quality control and processing requirements to ensure that the driven disc can operate stably and reliably in the clutch system. The exact manufacturing process and steps may vary by manufacturer and clutch type.