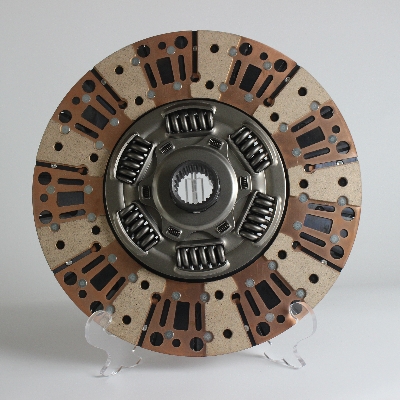

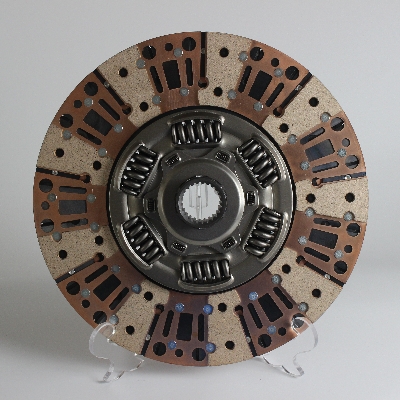

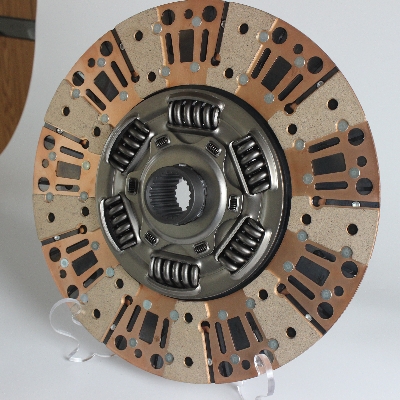

Ceramic Clutch Disc for Tipper Truck

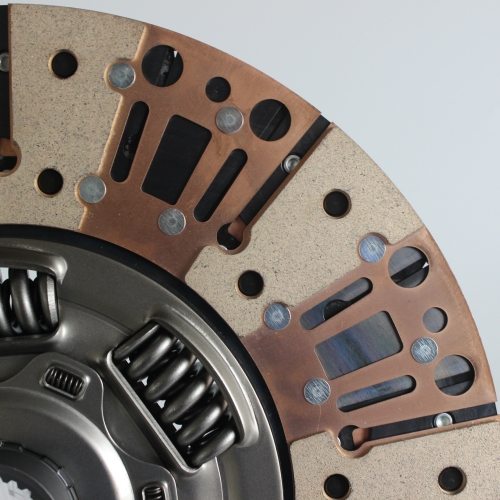

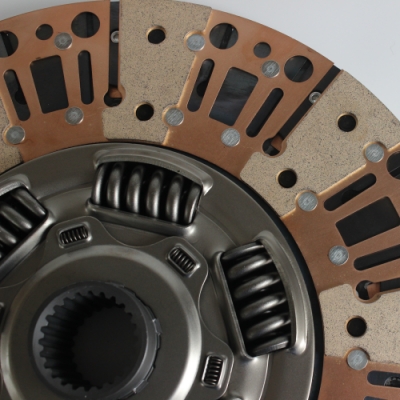

Highlight 1: The ceramic sheet is made of Austrian Miba ceramic block, which is resistant to high temperature, high friction coefficient, large torque, anti-fatigue and durable. Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

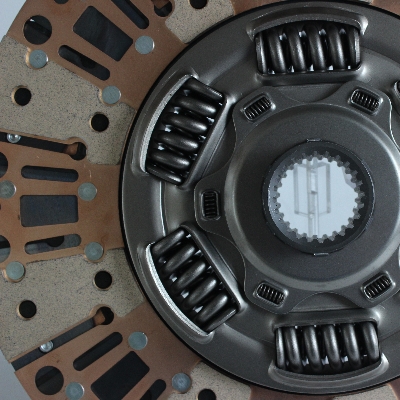

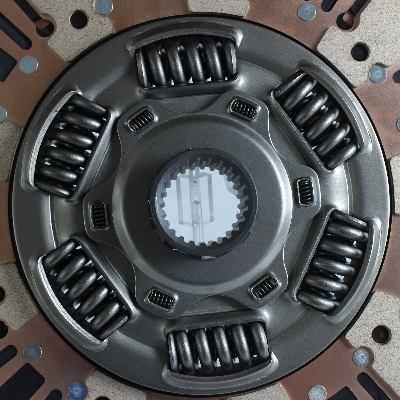

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Product description

The automobile clutch driven plate is a key component in the clutch and is installed between the flywheel and the pressure plate. During operation, the pressure plate is tightly pressed against the surface of the flywheel, and the engine power can be transmitted by relying on the friction between the friction lining on the driven plate and the surfaces of the flywheel and pressure plate.

A cermet automobile clutch driven disc, which includes a cermet friction lining, a driven disc, a shock absorbing spring, a shock absorbing spring pressure plate, a damping plate and a driven disc hub, and is characterized in that it also includes a bar-shaped compression spring ; There are three driven discs in total, including one large clover-shaped disc and two small disc-shaped discs. The discs are riveted with rivets. The three blades of the three-lobed disc are riveted with cermet friction. There are damping sheets stuck on both sides of the lining, the large clover-shaped piece and the small disc-shaped piece. The driven disc with the damping sheet stuck on it is placed on the driven disc hub; a shock absorber is placed in the rectangular hole of the driven disc. The spring, the front and rear of the shock absorbing spring are pressed with shock absorbing spring pressure plates, the driven disk hub and the front and rear shock absorbing spring pressure plates are riveted together with rivets, and bar-shaped compression reeds are placed under the rivets.

Packaging and shipping

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

Company strength

Shandong Litong Clutch Manufacturing Co., Ltd. is equipped with first-class production technology and manufacturing testing equipment. Its products have reliable performance and complete varieties, and are sold well in many provinces and cities across the country. The company is a professional manufacturer of automotive clutch assemblies integrating scientific research and development, manufacturing, sales and service. It strictly implements the IATF/16949 quality system requirements. Product quality fully complies with QC/T25-2004 industry standards. Selling well in many provinces and cities across the country, and exported to Europe, America, Southeast Asia, the Middle East and other countries.