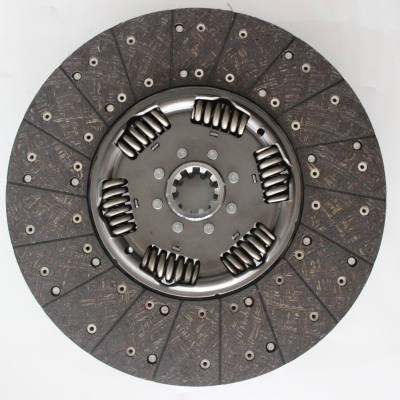

Ceramic Clutch Disc for Mining Truck

Highlight 1: The ceramic sheet is made of Austrian Miba ceramic block, which is resistant to high temperature, high friction coefficient, large torque, anti-fatigue and durable. Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Product Description

The automobile clutch driven plate is a key component in the clutch and is installed between the flywheel and the pressure plate. During operation, the pressure plate is tightly pressed against the surface of the flywheel, and the engine power can be transmitted by relying on the friction between the friction lining on the driven plate and the surfaces of the flywheel and pressure plate.

The vast majority of clutch driven plate friction materials are asbestos-reinforced resin materials (hereinafter referred to as organic sheets). This kind of organic sheet will fail prematurely due to thermal decay, thermal cracking and thermal expansion under heavy load and harsh working conditions, and has a short service life. At the same time, asbestos is a carcinogen, so the development of asbestos-free friction materials is one of the current focuses of friction material research. There are three main categories of asbestos-free friction materials: 1) Using new fibers to replace asbestos fibers, such as Kevlar (aramid) fiber, carbon fiber, etc., but they are expensive; 2) Using metal fibers and metal powder to make semi-metallic friction materials, and the matrix is also Still resin. 3) It is made of cermet material. Metal-ceramic friction materials have the characteristics of stable friction coefficient and small wear. They are especially suitable for heavy-duty vehicles (such as desert vehicles, load trucks, trailers, dump trucks and construction machinery such as cranes, forklifts, excavating machinery, etc.), and can also be used for ordinary vehicles. Clutch driven disc friction plates for medium-sized trucks and their modified vehicles.

The utility model relates to a cermet automobile clutch driven disc with a novel structure, belonging to the technical field of vehicle braking control.The structure of the clutch driven plate is often adapted to the material of the driven plate friction lining used. The driven disc consists of a large piece with a three-leaf shape and two small pieces with a round disc shape, which are riveted with 27 rivets. In addition to the 12 rivets on the front and rear shock absorber pressure plates and the driven disk housing, the total number of rivets reaches 39. The production process is relatively complicated, with many processes. Without special equipment, it is easy to cause deformation of the driven disc, and the number of molds and the amount of steel are large.

Packaging and shipping

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging

services.