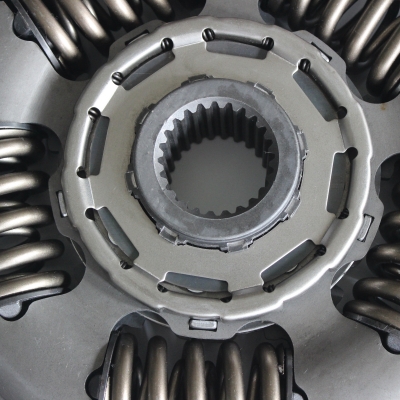

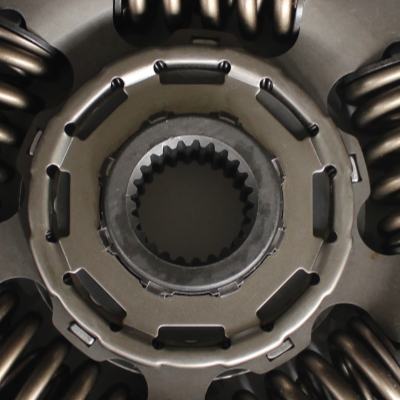

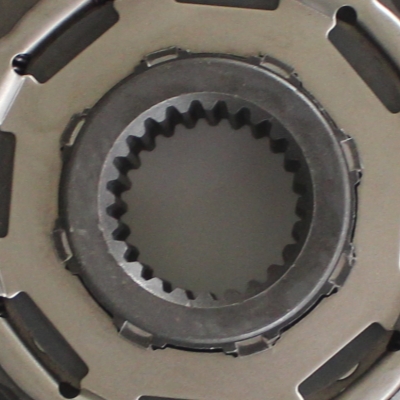

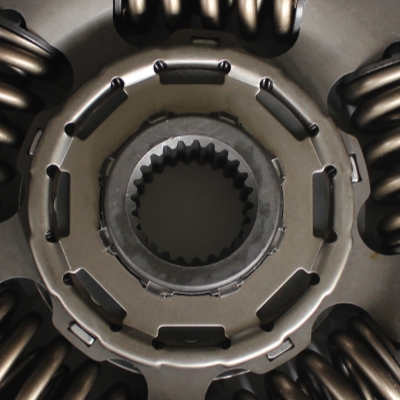

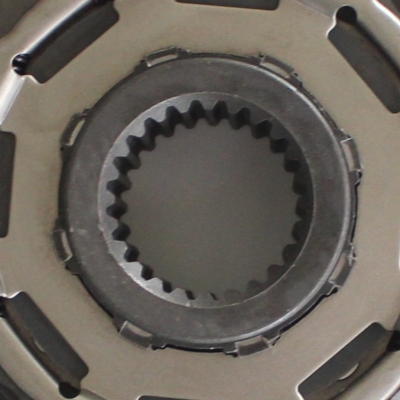

Clutch Disc For Mining Dump Truck

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Product description

The clutch is one of the important parts that make up the power transmission system, and the driven plate is one of the main parts of the clutch. It is a transmission device that exerts its transmission function through friction. During the clutch manufacturing process, it is difficult to ensure the flatness of the clutch friction plate due to the rebound deformation of the material.

The function of the pressure plate and the driven plate in the automobile clutch is to combine the two and transmit the engine power to the gearbox, which is power transmission. The friction plate is also called the clutch plate because it is connected or clutched through the friction clutch in the clutch. It is an important part of the clutch.

The clutch has three important functions: "transmitting power", "cutting off power" and "preventing overload".

Inspection method of clutch driven plate

(1) Detect the wear amount of driven plate friction plate

Use a vernier caliper to measure the depth of the rivet head to detect the wear of the friction plate. If the depth is less than 0.3mm, it means serious wear and the friction plate needs to be replaced.

(2) Detect the deformation of the driven plate

The degree of deformation can be checked by the deflection of the driven plate. Use a dial indicator to measure on the outer edge of the driven plate. The circular runout of the end face should not be greater than 0.4mm. If the circular runout of the end face exceeds 0.4mm, use a wrench to correct the driven plate, or replace the driven plate assembly. Otherwise, it will cause the clutch to shake when the car starts, incomplete clutch separation, difficulty in shifting, and other malfunctions.

(3) Check the connection status between the driven plate steel plate and the hub

It can be detected by hitting it with a hammer. If the rivet is loose or broken, it needs to be replaced.

(4) Check the matching clearance between the driven plate spline bushing and the gearbox input shaft spline shaft

If the gap is too large, it will affect the sound when the car starts or the speed changes suddenly. During the inspection, install the spline shaft of the driven plate on the first shaft spline of the gearbox, and run the driven plate back and forth by hand. No significant looseness is allowed. If the tooth side clearance exceeds 0.16mm, the driven plate should be replaced. hub or transmission input shaft.

Company strengths

We are the manufacturer of clutch plate assembly, clutch cover assembly, clutch release bearing, etc. Our product features:

1. Heat treatment and surface treatment make the clutch plate have low loss, no noise and long service life.

2. We have multiple models of clutch covers and clutch plates, and can develop clutch plates according to customers' drawings and samples.

3. OEM quality standards are guaranteed and prices are competitive.

4. Fast production and flexible and convenient logistics services. Clutch plates come in neutral box packaging or branded packaging with superior design and quality. We can also create custom packaging for your clutch plate with your own brand logo design.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible