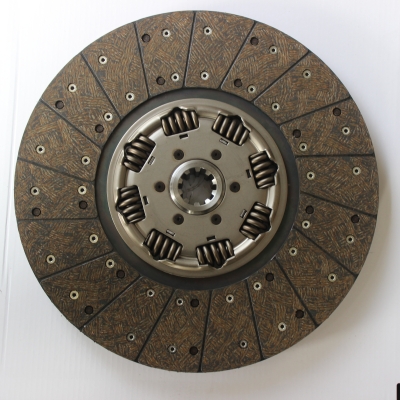

Clutch Disc Plate For Dump Truck

Highlight 1: The self-developed carbon fiber surface is specially designed for wide-body vehicles, which is stable and strong.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 6: Thickened back cover with countersunk holes, more firm riveting.

Product description

The automobile driven clutch plate is another part of the clutch. It transmits the engine torque to the transmission through friction conversion, reduces the vibration and impact of the transmission system, and plays the role of "disconnection" and "grafting". The automobile clutch plate is an essential wearing part for manual transmission cars. The clutch driven plate hot-pressing leveling device physically deforms the material under constant temperature and constant pressure conditions, ultimately achieving leveling of the driven plate, and at the same time improving the wear resistance and stability of the clutch driven plate transmission.

The automobile clutch driven plate is an indispensable wearing part for manual transmission cars.

1. The appearance and geometric dimensions of this product are the same as the original ordinary driven disk, and the installation method is simple.

2. The gear shifting operation is simple and smooth during normal driving. No need to press the clutch pedal, just pump out the oil and shift gears as needed. (The clutch pedal still needs to be pressed when the car starts, shifts into first gear, and reverses.)

3. Extend the life of vehicle-related components. Since the clutch pedal is not depressed when shifting gears during normal driving, the clutch is in a combined state at this time, which reduces the wear of the pressure plate and driven plate, and also reduces the action frequency of the cable, release bearing and other parts.

4. Reduce fuel consumption and promote environmental protection. Since the clutch is engaged when shifting gears while the vehicle is driving, power transmission is uninterrupted, reactive power loss is small, and speed is high. Under the same road conditions, this technology product reduces fuel consumption by about 15% than traditional products, and also reduces exhaust emissions by about the same proportion.

Packaging and shipping

In order to better protect the safety of your goods, we provide professional, environmentally friendly, convenient and efficient packaging services.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible