Clutch Disc Plate for 40 Tons XDA40 XCMG

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

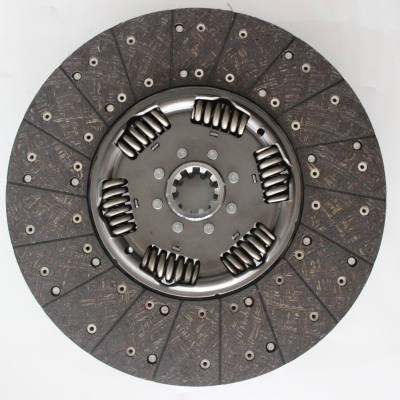

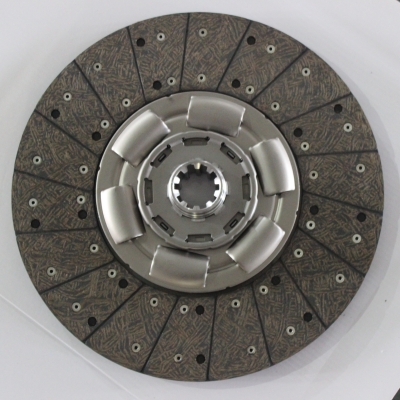

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

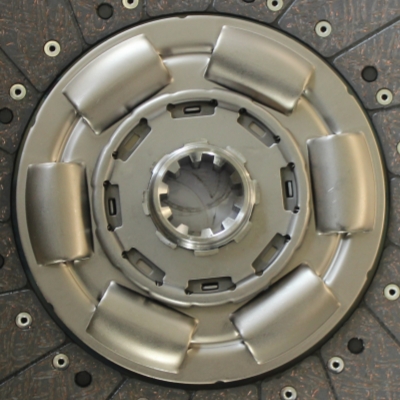

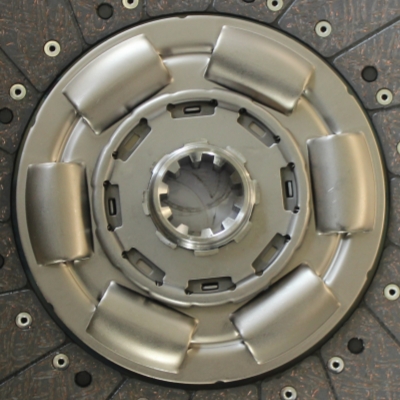

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Product description

The clutch drive plate mainly consists of the drive plate, drive plate hub, friction plate and other parts.

1. The material of the driven parts is related related to the structural model used

2. Followers without wave spring blades usually It is forged from high carbon steel or spring hardened parts and has been heat treated to provide This meets the hardness requirements.

3. When using a wave spring plate, the follower should be made of Low carbon steel and corrugated parts should be made. from spring steel

4. Drive disc hubs are generally made of 26-32HRC cast iron.

5. Clutch Construction: A clutch mainly consists of a control part, a transmission part, a contact, a friction plate, etc. They work together to provide a smooth and stable performance. The clutch works efficiently.

6. Working principle: The clutch controls the movement of the The control panel and gear sections are connected to the contact points, so power from the engine is transmitted. to the drive system He can also close the clutch and to change gears through the transmission system when the engine starts nt to the position specified by the controller.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

Testing Equipment

Packaging and shipping

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

Company strength

Shandong Litong Clutch Manufacturing Co., Ltd. is an enterprise specializing in the production of brakes and clutches. We can provide brake and clutch parts for the most popular vehicles in Europe, the United States and other markets. Our well-equipped facilities and excellent quality control throughout the production stages enable us to guarantee complete customer satisfaction. We have obtained TS:16949 certification, LH is our brand, quality is our culture, high quality and competitive prices are Our purpose. We have established solid cooperative relationships with customers in more than 30 countries,

We look forward to a brighter and more successful business in the near future.

We are professional in making and designing various clutch accessories and brake parts!if you are interested,ust feel free to contact us,we will be at your service any time!