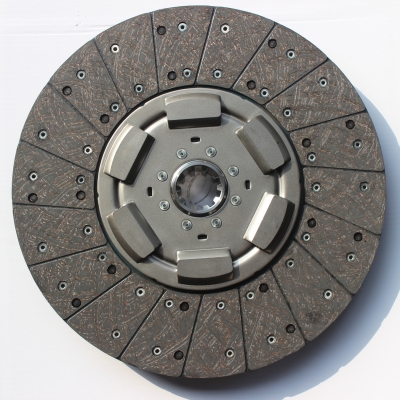

Clutch Disc Plate For XDE200 XCMG

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Product description

The clutch is located in the flywheel housing between the engine and gearbox. The clutch driven plate is mainly composed of a driven plate body, a friction plate and a driven plate hub. Specifically, it can be said that it is composed of four parts: driven steel plate, friction plate, torsion damper, and driven disc hub. Driven steel plate: The driven steel plate is riveted to the torsional shock absorber disc, and the driven disc hub is sandwiched between them. Friction plate: transmits torque. Torsional shock absorber: can effectively prevent torsional vibration in the transmission system. Driven hub, etc.: transmit torque. The driven plate is another component of the clutch. It transmits the engine torque to the transmission through friction conversion, reducing vibration and impact of the transmission system, and completing the tasks of "cutting" and "inserting".

Its basic requirements are smooth connection, quick and complete separation, easy adjustment and maintenance, small size, small mass, good wear resistance and sufficient heat dissipation capacity, and easy and labor-saving operation. Generally, there are two types: gear type and friction type.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

Packaging and shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company strength

Shandong Litong Clutch Manufacturing Co., Ltd. is a manufacturer of clutch plate assemblies, clutch cover assemblies, clutch release bearings, etc. that integrates scientific research and development, production and manufacturing, sales and services. The company has an annual production capacity of 1.1 million sets of clutch driven plate assemblies and 600,000 sets of pressure plate assemblies. Our product features: through heat treatment and surface treatment, the clutch plate has low loss, no noise and long service life. It has first-class production technology and manufacturing testing equipment. Litong series products have reliable performance and complete varieties, and are sold well in many provinces and cities across the country. Product quality fully complies with QC/T25-2004 industry standards. Selling well in many provinces and cities across the country. We supply high-horsepower mining trucks to well-known enterprises such as Li Heavy Industry, Shandong Lingong, Zhongtong Bus, Beijing Public Transport, Liaocheng Transportation, etc., and export them to Europe, the United States, Southeast Asia, the Middle East and other countries.