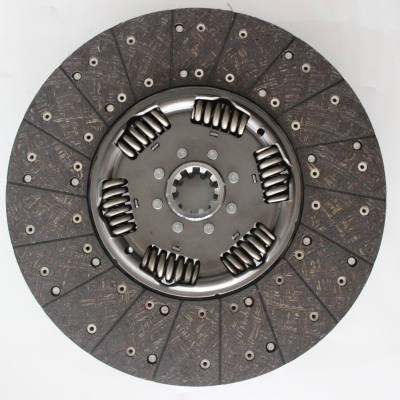

Clutch Disc Plate For Mine Dump Truck

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

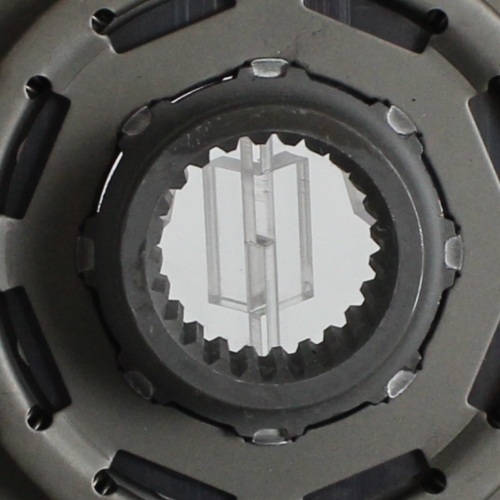

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Product details

The clutch is an important component required in a vehicle's transmission system. The structure and working principle include a controller. Components of the transmission system, contacts, friction plates, etc., when working together The clutch will work more efficiently. A car's clutch drive plate is an important wear and tear part of a manual transmission car. The hot plate leveling device driven by the clutch causes the physical deformation of the material under constant temperature and constant pressure conditions. This will eventually allow you to adjust the level of the driver board. At the same time, the wear resistance and transmission stability of the clutch drive plate can be improved. The clutch disc is an important part of a car's braking system. Located between the engine flywheel and the gear input shaft. When you step on the pedal The steering wheel transfers the engine's rotational energy to the transmission. Properly adjust the tool for acceptable power transfer.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | Clutch Disc |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

Clutch driven plate production process

1. Design plan: According to the needs and requirements of the clutch system, determine the pressure plate layout and planning plan. This includes searching for elements such as material, size and shape.

2. Material preparation: Choose a fabric suitable for making clutch plates. Depending on your needs, you may need to cut and shape it.

3. Production molding: Use advanced technology and tools to produce pressure plates according to the design plan. Basically, calico is converted into a cover by milling, turning, stamping, etc.

4. Surface treatment: The clutch plate is coated with necessary primer to achieve optimal friction performance and wear resistance. This may include strategies such as heat treatment, grinding, plating and coating.

5. Functional testing: Functional testing is performed on the manufactured clutch disc to ensure it meets specified specifications and performance.

6. Packaging and Shipping: Inspected clutch discs are securely packaged, labeled, and shipped to the consumer or manufacturer for disposal. Additional signage, instructions or preliminary inspection may be required, depending on your needs.

Packaging and shipping

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.