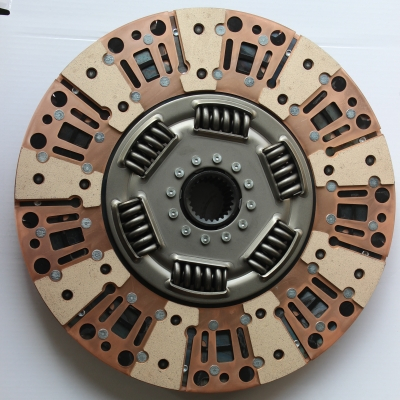

Clutch Disc For XDE200 XCMG

Highlight 1: The self-developed carbon fiber surface is specially designed for wide-body vehicles, which is stable and strong.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 6: Thickened back cover with countersunk holes, more firm riveting.

Product description

The car's clutch driven plate is another component of the clutch. It transmits the engine torque to the transmission through friction conversion, reducing vibration and impact of the transmission system, and completing the tasks of "cutting" and "inserting". The automobile clutch driven plate is an essential wear part for manual transmission cars. The clutch driven plate hot pressing leveling equipment physically deforms the material under constant temperature and constant pressure conditions, and finally achieves the leveling of the driven plate. At the same time, the wear resistance and transmission stability of the clutch driven plate can be improved.

The driven plate is a key component in the design of the clutch hot pressure leveling device

The main components of hot pressure leveling equipment mainly include mechanical systems, molds and hydraulic systems.

1. Mechanical system. A transmission system that combines hydraulic transmission and guide post guide mechanism is used to match the hot-rolled leveling characteristics of the clutch driven plate. In order to ensure the stability and reliability of the leveling device, the overall support structure adopts a vertical four-point guide pillar support mechanism.

2. Mold. The clutch driven plate is flattened by pressing with convex and concave molds under constant temperature and constant pressure conditions. In order to meet the requirements of constant temperature and constant pressure, the mold material is W18Cr4V high-speed steel, which can maintain high hardness and wear resistance even at high temperatures, ensuring the quality and stability of the clutch driven plate leveling.

Packaging and shipping

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

Company strength

Shandong Litong Clutch Manufacturing Co., Ltd. is equipped with first-class production technology and manufacturing testing equipment, and its products have reliable performance and full variety, and are well sold in many provinces and cities across the country. The company is a professional manufacturer of automotive clutch assemblies that integrates scientific research and development, manufacturing, sales and service, and strictly implements IATF/16949 quality system requirements. Product quality is fully compliant with QC/T25-2004 industry standard. It sells well in many provinces and cities across the country, and we cooperate with well-known enterprises such as XCMG Heavy Trucks, Cone Heavy Industries, Shandong Lingo, Zhongtong Bus, Beijing Public Transportation, Liaocheng Transportation, and provide high-quality support materials. doing. Horsepower mining trucks are exported to Europe, America, Southeast Asia, the Middle East and other countries.