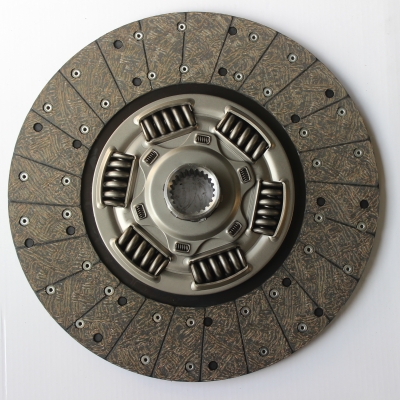

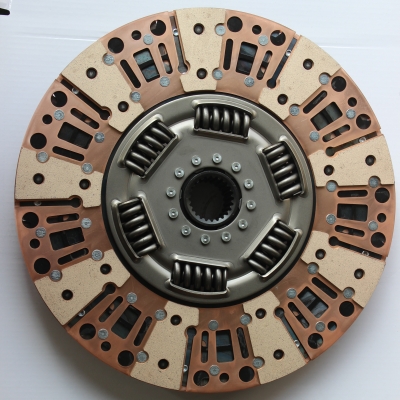

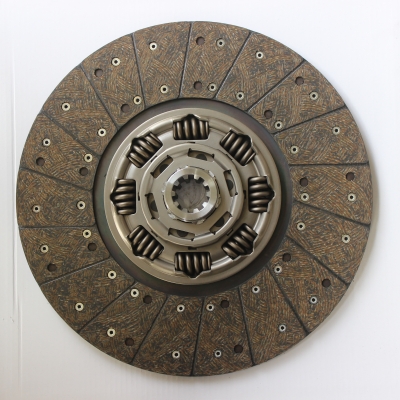

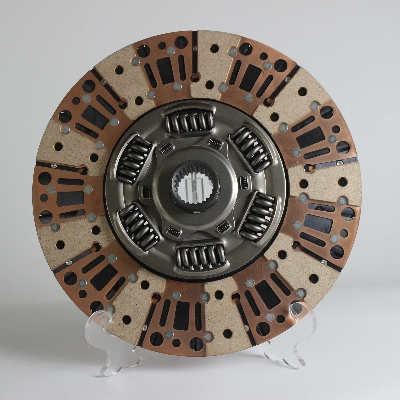

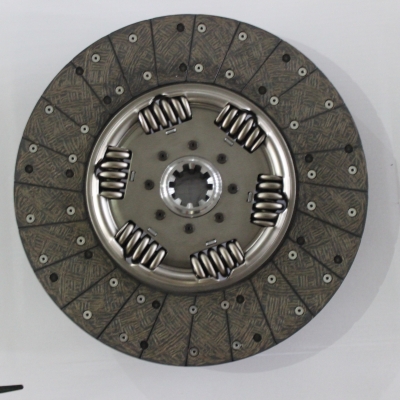

Clutch Disk For 40 Tons XDR80TE

Highlight 1: The self-developed carbon fiber surface is specially designed for wide-body vehicles, which is stable and strong.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 6: Thickened back cover with countersunk holes, more firm riveting.

Product description

The car's clutch driven plate is also a clutch component. It transfers engine torque to the transmission through friction conversion. Helps reduce vibration and shock in the driveline. And play a role in "disconnecting" and "connecting" the car clutch transmission plate is an important wear part of manual transmission vehicles. The clutch-driven hot press drives the plate leveling device to physically deform the material under constant temperature and pressure conditions. Finally, the transmission plate is leveled to improve the wear resistance and transmission stability of the clutch transmission plate.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

What will happen if the clutch driven plate is broken?

A broken clutch driven plate will cause the clutch to shake when the car starts, incomplete clutch separation, difficulty in shifting gears, and other malfunctions.

The clutch driven plate is the worst-working and most easily damaged component in the clutch. If the driven friction plate is visually inspected for serious damage, cracking, ablation, etc., the friction plate must be replaced; if the overall deformation and deflection require inspection and correction; if the gap between the spline bushing and the output shaft spline exceeds the specification, it must be replaced.

Testing Equipment

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.