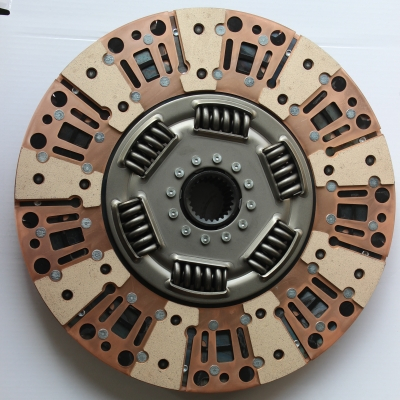

Clutch Disk For 86 Ton XKT136 XCMG

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Clutch working principle:

The clutch is located in the flywheel housing between the engine and transmission. It consists of friction plates, spring plates, pressure plates, and power output shafts. It is located between the engine and the gearbox. The engine oil is stored in the flywheel of the engine. When the driver depresses the clutch, the clutch will actually loosen. This will temporarily disconnect the engine and transmission. The clutch will actually start to move when the driver releases the clutch pedal. In this way, the engine's power is transferred to the transmission system. When the clutch pedal is slowly released, the clutch gradually tightens, the engine load gradually increases, and the engine flywheel gradually tightens. Drive gear set The car starts to move slowly. And it definitely won't stop.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

Packaging and shipping

Company strength

Lihong Holding Group Co., Ltd. has a complete range of products, some of which have entered the European and North American markets. The company has strong technical force. Its main technical personnel and management personnel have many years of professional knowledge and experience in clutch product development and production. They have received strict training from professional clutch manufacturers in Germany and are familiar with domestic and foreign clutch manufacturing processes and various technical standards. Strong product development capabilities, product design cycle is two months. The company's employees have undergone strict training and have high quality. Product assemblies undergo rigorous comprehensive testing before leaving the factory. The production site has a complete range of testing methods, including diaphragm spring load characteristics, separation endurance fatigue test, cover assembly comprehensive characteristics, driven plate working conditions, driven plate damping characteristics, torsional stiffness and torsional fatigue test testing machines. These testing equipment They all use computer control technology, and 100% of the products have been strictly inspected in each process. The products they produce are comparable to well-known domestic and foreign manufacturers in terms of appearance, structure, service life, operation performance, etc.