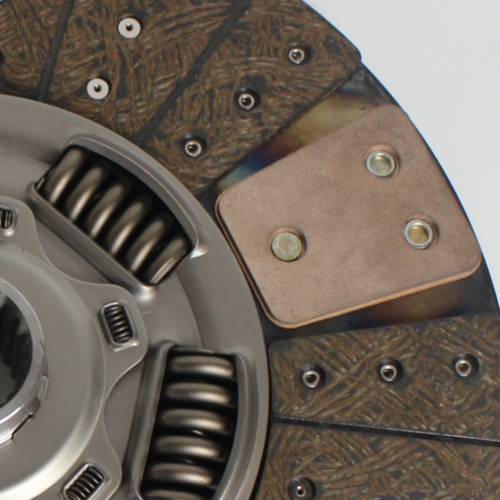

Clutch Disk For Off-road

Highlight 1: The ceramic piece adopts Austrian Miba ceramic block, which is resistant to high temperature, high friction coefficient, large torque, fatigue resistance and durability.

Highlight 2: Made of 65m heat-treated steel plate, durable and thermoset.

Highlight 3: The corrugations are laser-bent, and the starting gear is smooth, reducing clutch damage.

Highlight 4: The splines have been tempered in a vacuum furnace to make the pre-shock absorbing structure more sensitive and rigid and solve idle vibration.

Highlight five: Using 55 chromium silicon to solve the problem of spring shaking and breakage in large vehicles.

Product description

The vehicle clutch plate is an important component of the engineering vehicle power system and is responsible for cutting off and connecting the power transmission from the engine to the drive shaft. Conventionally used traditional semi-ceramic and organic clutch plates have a short service life, and their quality is easily affected by factors such as the external environment and driver's operating habits. The project technical team combined the existing problems of the clutch plate and selected a new "ceramic clutch plate" with more advantages, which has the advantages of durability, strong stability, low damage rate and high safety. The average use time of the new ceramic clutch plate is about twice that of ordinary semi-ceramic and organic clutch plates, and the damage rate is only 2%, which greatly reduces maintenance costs, improves on-site driving safety, and is conducive to project cost control and safety production management.

Working principle of the clutch:

The clutch is located in the flywheel housing between the engine and the gearbox. It is composed of friction plates, spring plates, pressure plates and power output shafts. It is arranged between the engine and the gearbox to store the oil on the engine flywheel. The torque is transmitted to the transmission. When the driver depresses the clutch pedal, the clutch is actually separated, so that the engine and the transmission can be temporarily separated; when the driver releases the clutch pedal, the clutch is actually combined. In this way, the power of the engine can be transmitted to the gearbox; when you slowly loosen the clutch pedal, the clutch will slowly tighten, the load on the engine will slowly increase, and the flywheel of the engine will slowly drive the gearbox. When the input shaft rotates, the car will slowly start to move and naturally it will not stall.

Company strength

Lihong Holding Group Co., Ltd. was founded in 1978. It is a professional group company integrating R&D, production, sales services and international trade of high-end composite materials, clutch friction plates, and clutch assemblies. In order to strictly control product quality, Lihong has introduced modern testing equipment, and strictly implements the ISO/TS16949 quality system requirements on the basis of national standards. Product quality fully complies with QC/T25-2004 industry standards, and has established an international advanced testing system product testing center.