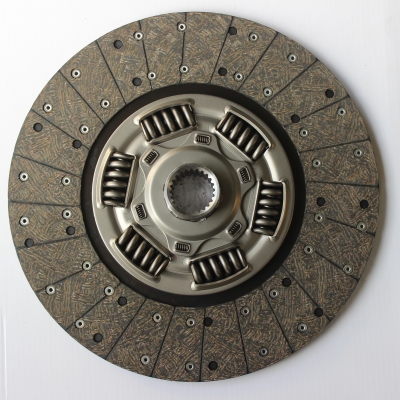

Clutch Friction Plate For XKT136 XCMG

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

The driven plate assembly is mainly composed of friction plate, driven plate, shock absorber and spline hub. The driven plate has a great influence on the working performance of the clutch and should meet the following design requirements:

1. The moment of inertia should be as small as possible to reduce the impact between gear teeth when the transmission is shifting.

2. It should have axial elasticity to make the clutch engagement smooth and easy to start, and to make the pressure on the friction surface uniform and reduce wear.

3. A torsional shock absorber should be installed to avoid resonance of the drive train and mitigate impact.

In order to make the driven plate axially elastic, commonly used methods are:

A "T"-shaped groove is opened on the driven plate, and many fan shapes are formed on the outer edge, and the fan-shaped parts are stamped into wavy shapes that are bent in different directions. The friction plates on both sides are riveted on every other sector. The "T" shaped groove can also reduce the warping deformation of the driven plate caused by frictional heat. This structure is mainly used on trucks.

Rivet the left and right raised sections of the sector-shaped corrugated plate to the left and right friction plates respectively. Since the corrugated plate is thinner than the driven plate, this structure has better axial elasticity and smaller moment of inertia, and is suitable for high-speed rotation. It is mainly used in cars and light trucks.

Use the thin section of the stepped rivet rod to rivet the left piece of the pair of corrugated plates to the left friction plate, and alternately rivet the right piece to the right friction plate. This structure has a large elastic stroke and ideal elastic characteristics, which can make the car start extremely smoothly. It is mainly used in mid- to high-end cars.

The left friction plate close to the flywheel is directly riveted to the driven plate. Only the driven plate close to the pressure plate is riveted with a corrugated plate. The right friction plate is riveted to the corrugated plate with rivets. This structure has a large moment of inertia, high strength, and large torque transmission capacity. It is mainly used in trucks, especially heavy trucks.

Product Testing Equipment

Packaging and shipping