Clutch Plate And Disc For Mining Truck

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

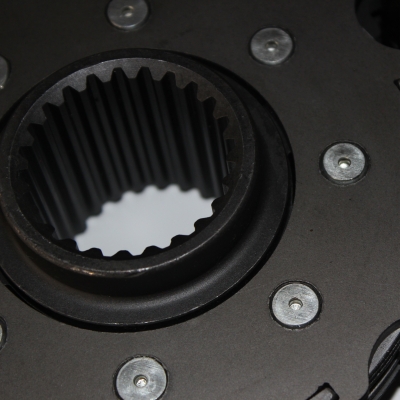

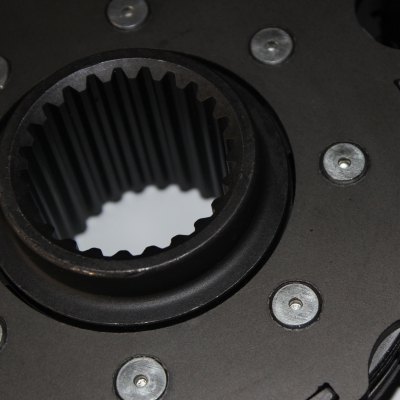

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Product description

The clutch driven plate is an important part of the clutch. Typically a round steel plate with friction material attached to the engine crankshaft that transmits engine power to the transmission.

The hot press leveling machine is mainly composed of mechanical system, hydraulic system, heating system and electrical system. The mechanical system is the main part of the hot press leveling machine. Hydraulic systems are catalysts that allow precise regulation of pressure. The heat sink consists of a resistive wire and an optocoupler sensor to monitor temperature changes on the machining plate. Electrical systems can sense and monitor changes in pressure and temperature in real time.

The working principle of the hot-pressing leveling equipment is to insert the clutch transmission plate into the mold of the hot-pressing leveling equipment. The upper and lower hot plates heat the mold. Once the mold reaches the specified temperature, the edges are free to move. The mold is heated by a water driven system. The upper and lower molds with the pressure plate are structurally close to each other. At the same time, uneven movement of the upper and lower templates should be avoided. When the position of the movable mold reaches a predetermined height, the plate mold used is heated and pressure is applied. Precisely control pressure and temperature changes so that temperature and pressure compensation remain stable over a specified period of time. Verify that the transmission plate thickness meets design requirements.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

Packaging and shipping

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.