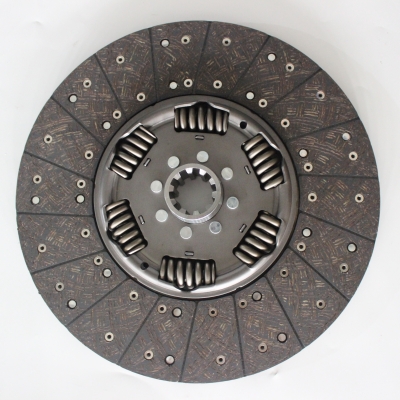

Clutch Plate And Disc For Tipper Truck

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

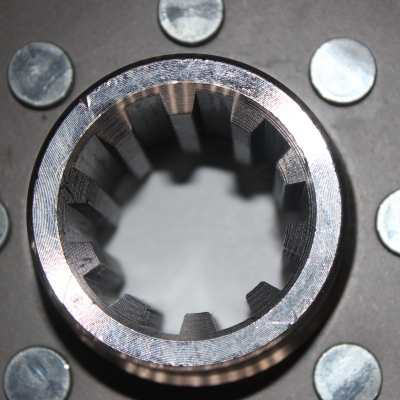

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Product description

The clutch disc is an important component of a vehicle's braking system. Located between the engine flywheel and the gear input shaft. When you step on the pedal The handle transfers the engine's rotational energy to the transmission. and adjust the tool properly for acceptable power transfer. When changing the brake disc It is often recommended to replace the entire grip assembly. Including strain plate and starter bearing. To get a complete and balanced system Consult your vehicle manufacturer's specifications for guidance. Or ask for expert advice to make the right decision. and set the disc brakes according to your car model and driving needs.

The drive plate is a key component in the design of the clutch's hot rolling adjustment device. The main components included in most hot press leveling equipment are the mechanism, mold, and hydraulic system.

1. Mechanical system A power transmission system combining a hydraulic transmission and a guide post mechanism is used to match the hot-rolled leveling characteristics of the clutch drive plate. To ensure the stability and reliability of the leveling equipment. Therefore, a four-point vertical guide pillar support mechanism is used as the overall support structure.

2. Mold The leveling of the clutch drive plate is achieved by pressing a convex and concave mold under constant temperature and pressure conditions. To meet the requirements for constant temperature and constant pressure. The mold material is therefore W18Cr4V high speed steel, which maintains high hardness and wear resistance even at high temperatures. Helps ensure quality and stability of clutch drive plate adjustment.

Packaging and shipping

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.