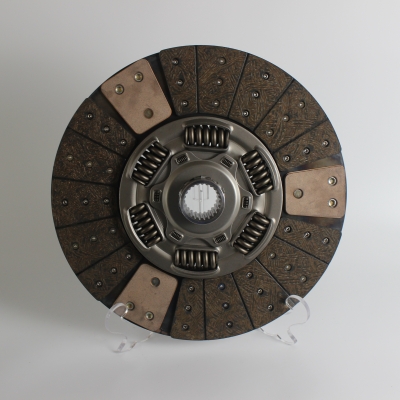

Friction Plate For Mine Dump Truck

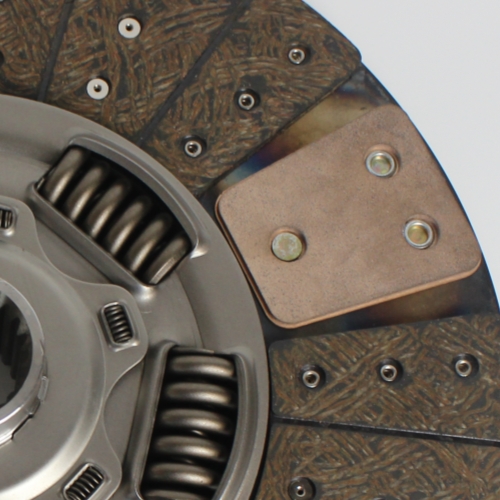

Highlight 1: The ceramic sheet is made of Austrian Miba ceramic block, which is resistant to high temperature, high friction coefficient, large torque, anti-fatigue and durable.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Product Description

The driven plate assembly is mainly composed of friction plate, driven plate, shock absorber, spline hub, etc. The driven disc has a significant impact on the operating performance of the clutch and must meet the following design requirements:

1. The moment of inertia should be as small as possible to reduce the impact between gear teeth when the transmission shifts gears.

2. The clutch requires axial elasticity to ensure smooth engagement and startability, as well as equalize the pressure on the friction surface and reduce wear.

3. A torsional damper should be installed to avoid resonance in the transmission system and reduce impact.

In order to make the pushed plate axially elastic, often used strategies are:

A "T"-shaped groove is opened on the pushed plate, and many fan shapes are fashioned on the outer edge, and the fan-shaped components are stamped into wavy shapes that are bent in one of a kind directions. The friction plates on each facets are riveted on each different sector. The "T" fashioned groove can additionally minimize the warping deformation of the pushed plate induced by way of frictional heat. This shape is commonly used on trucks.

Rivet the left and proper raised sections of the sector-shaped corrugated plate to the left and proper friction plates respectively. Since the corrugated plate is thinner than the pushed plate, this shape has higher axial elasticity and smaller second of inertia, and is appropriate for high-speed rotation. It is ordinarily used in vehicles and mild trucks.

Use the skinny part of the stepped rivet rod to rivet the left piece of the pair of corrugated plates to the left friction plate, and alternately rivet the proper piece to the proper friction plate. This shape has a giant elastic stroke and best elastic characteristics, which can make the automobile begin extraordinarily smoothly. It is basically used in mid- to high-end cars.

The left friction plate shut to the flywheel is immediately riveted to the pushed plate. Only the pushed plate shut to the stress plate is riveted with a corrugated plate. The proper friction plate is riveted to the corrugated plate with rivets. This shape has a giant second of inertia, excessive strength, and massive torque transmission capacity. It is usually used in trucks, in particular heavy trucks.