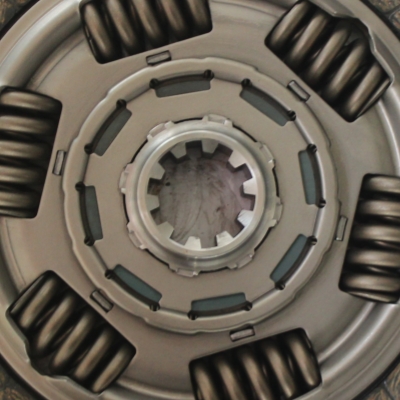

Friction Plate For Tipper Truck

430 Sinotruk T7 special 52.5

Highlight 1: 65 m heat-treated metal plate is used, which is long-lasting and heat-set.

Highlight 2: The corrugated plate is bent with the aid of laser, and the beginning equipment is clean to limit the grab damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-show absorption shape greater sensitive and firm, and to remedy the idle vibration.

Highlight 4: Use fifty five chrome silicon to remedy the issues of trembling and damaged springs of heavy-duty vehicles.

Highlight 5: The lower back cowl is laser welded, which is no longer effortless to crack.

Highlight 6: Adopt self-developed surface, especially designed for heavy-duty vehicles.

Product description

The pressure plate of the clutch is attached to the engine flywheel and rotates with the engine. The driven plate (friction plate) is splined to the input shaft of the gearbox through a spline groove. When the friction plates rotate, the transmission input shaft also rotates. When the pressure plate pushes against the driven plate due to the action of the spring, power is transmitted, but when the pressure plate returns to the position where the clutch pedal is depressed, the driven plate becomes weakly separated. ; If the pressure plate spring cannot fully exert its effect even if the clutch is lightly depressed, this is a semi-clutch, also called semi-linkage.

Packaging and shipping

Our Service

1. OEM production is welcome: products, packaging...

2. Sample order

3. We will respond to your inquiry within 24 hours.

4. After sent, we will track the item every two days until arrival. Once you receive the item, please test it and provide us with feedback. If you have any questions about this issue, please contact us. We will provide you with a solution.