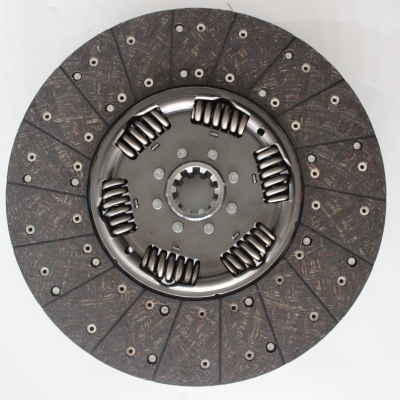

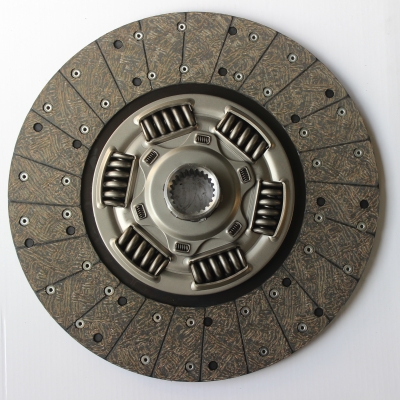

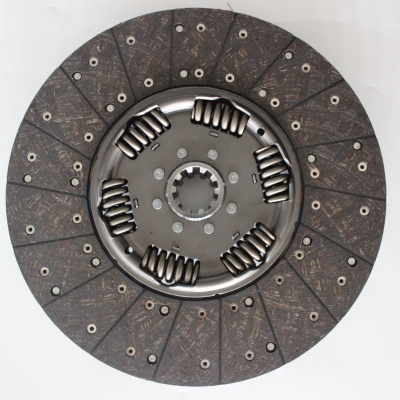

Multi Clutch Plate For XCMG

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: It adopts self-developed organic noodles, which are specially designed for heavy-duty vehicles.

Product description

The clutch is located in the flywheel housing between the engine and transmission. Protects the transmission system from overload. When the car brakes suddenly, it will decelerate rapidly, because without the clutch the engine is tightly connected to the transmission. Therefore, all moving parts experience significant inertia. This can cause the load on the drivetrain to exceed its load capacity. This can damage mechanical parts, but clutches eliminate this danger by taking advantage of the relative motion that can occur between the actuating and driven parts of the clutch. Therefore, to ensure safety, a clutch is required to limit the maximum torque that the transmission can handle.

Basic requirements for a clutch include smooth connection. Quick and complete separation Easy adjustment and maintenance Small external dimensions, low mass, good wear resistance, and sufficient heat dissipation capacity. Easy operation and labor saving There are two types commonly used: gear type and friction type.

Some of the main functions of a clutch are:

1. Efficient power transmission: The clutch plate effectively transmits power from the engine to the gearbox. Smoothly engages and disengages engine power as needed. Helps your car shift gears, transfer power and achieve maximum performance.

2. Smooth gear meshing: Properly designed clutch plates ensure smooth and continuous meshing of the engine and transmission. This results in smoother shifts and reduces wear on transmission components. This improves driving comfort and reduces shock and noise when shifting gears.

3. High Torque Capability: Clutch plates are designed to withstand the high torque produced by powerful engines. Designed to support engine power and torque. Guarantees optimal power transmission and prevents slippage and damage to the clutch assembly.

Packaging and shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company strength

Shandong Litong Clutch Manufacturing Co., Ltd. is a professional automobile clutch assembly manufacturer integrating scientific research and development, production and manufacturing, sales and services. The company has an annual production capacity of 1.1 million sets of clutch driven plate assemblies and 600,000 sets of pressure plate assemblies, and has first-class production technology and manufacturing testing equipment. Strictly implement IATF/16949 quality system requirements and fully comply with QC/T25-2004 industry standards. Selling well in many provinces and cities across the country, and exported to Europe, America, Southeast Asia, the Middle East and other countries.