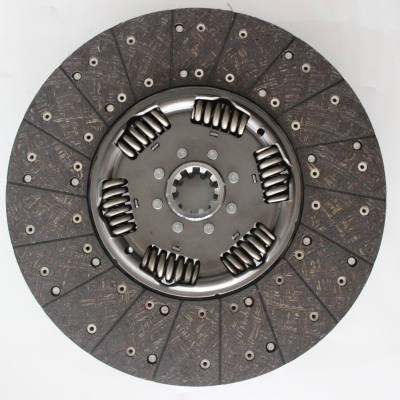

Twin Disc Clutch for Mining Truck

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: Use 55 chrome silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Product description

The automobile clutch drive plate is another component of the clutch. It transmits engine torque to the transmission through friction conversion. Reduce the vibration and shock of the transmission system, and complete the "disengagement" and "engagement" work. The automobile clutch drive plate is an indispensable and consumable part of the manual transmission vehicle. The clutch-driven hot press powered plate leveling device finally achieves the powered plate leveling by physical material deformation under constant temperature and constant pressure conditions. at the same time This process can improve the wear resistance and transmission stability of the clutch drive plate.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

Clutch working principle:

The clutch is located in the flywheel housing between the engine and transmission. It consists of friction plates, spring plates, pressure plates, and power output shafts. It is located between the engine and the gearbox. The engine oil is stored in the flywheel of the engine. When the driver depresses the clutch, the clutch will actually loosen. This will temporarily disconnect the engine and transmission. The clutch will actually start to move when the driver releases the clutch pedal. In this way, the engine's power is transferred to the transmission system. When the clutch pedal is slowly released, the clutch gradually tightens, the engine load gradually increases, and the engine flywheel gradually tightens. Drive gear set The car starts to move slowly. And it definitely won't stop.

Packaging and shipping

Company strength

Our company is a professional manufacturer of automotive clutch driven plates and pressure plate assemblies, and has passed ISO9001 quality management system certification. The driven disc surface is made of high-quality asbestos winding sheets and asbestos-free ones, which have the advantages of wear resistance and high temperature resistance. The steel sheets and upper and lower pressure plates have been carbonitrided and have the characteristics of high hardness, strong elasticity, and good mechanical properties. . We also developed copper-based friction discs and ceramic-iron friction discs to bring the quality of the driven plate to the domestic advanced level. The clutch cover and pressure plate castings in the spiral spring pressure plate assembly are made of 600-3 spherical cast iron. In the diaphragm spring pressure plate assembly, the gland is pressed from Baosteel SPHE deep-drawn high-quality steel plates, and the diaphragm spring is made of Domestic and foreign high-quality CrMnVA spring steel plates have been subjected to high-frequency quenching treatment and passed strict testing by the pressure plate assembly comprehensive performance testing machine before leaving the factory. The internal quality control standards of the clutch assembly are higher than the QC/T25-92 national standard, and it has strong strength, good stability, wear resistance, and long service life.