Twin Disc Clutch For Tipper Truck

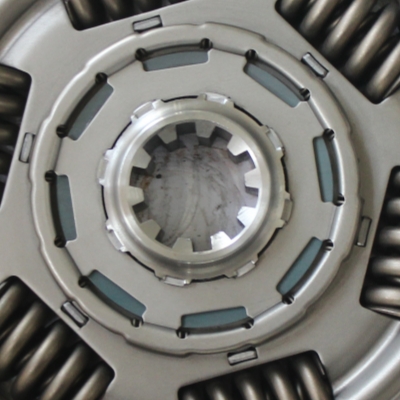

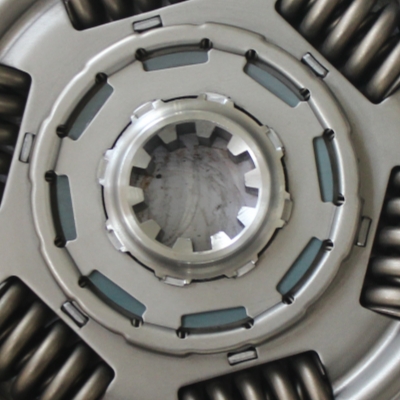

Highlight 1: The self-developed carbon fiber surface is specially designed for wide-body vehicles, which is stable and strong.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 6: Thickened back cover with countersunk holes, more firm riveting.

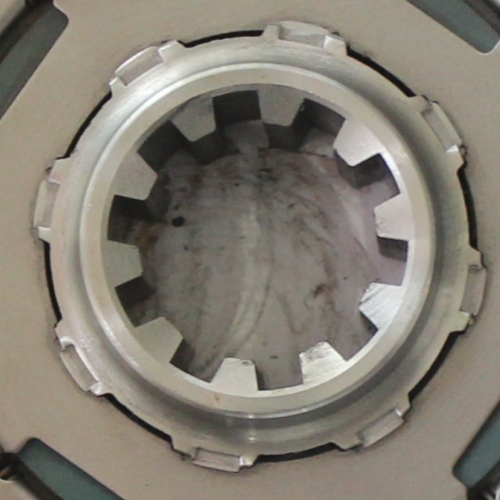

The driven plate is necessary for hot pressure leveling of the clutch.

The driven plate is one of the key components of the clutch, and the clutch is a transmission device that relies on friction to perform transmission functions. During the clutch manufacturing process, due to the rebound deformation of the material, it is difficult to ensure the flatness of the clutch friction plate. The traditional leveling method is usually manual leveling or cold press leveling. Manual leveling has low production efficiency, high cost, and high scrap rate; after cold press leveling, the rebound is large and the leveling effect is poor. Hot press leveling is difficult to operate. The specific manifestation is that the surface of the driven plate contains convex and concave parts. During the pressurization process, the convex and concave parts must be avoided. In addition, excessive temperature during the heating process will cause annealing of the parts. Excessive temperature will cause the parts to anneal. If it is too low, the leveling requirements cannot be met. It can be seen that only by controlling the pressure and temperature within a certain range can qualified products be produced. The clutch driven plate hot pressing leveling equipment finally achieves the leveling of the driven plate by physically deforming the material under constant temperature and constant pressure conditions. At the same time, this process can improve the wear resistance and transmission stability of the clutch driven plate.

Company strength

Lihong Holding Group Co., Ltd. was founded in 1978. It is a professional group company integrating R&D, production, sales services and international trade of high-end composite materials, clutch friction plates, and clutch assemblies. In order to strictly control product quality, Lihong has introduced modern testing equipment, and strictly implements the ISO/TS16949 quality system requirements on the basis of national standards. Product quality fully complies with QC/T25-2004 industry standards, and has established an international advanced testing system product testing center.