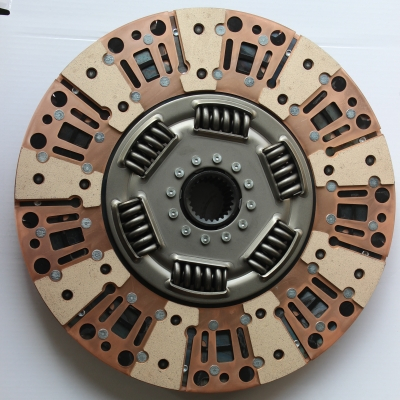

Wide-body Truck Clutch Disc

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: Use 55 chrome silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: Adopt self-developed surface, specially designed for heavy-duty vehicles.

Product function

The driven plate can also be called the rear pressure plate, which gives a force to the clutch friction plate from behind, causing the friction plate to move forward slightly and compress the driving plate (front pressure plate, flywheel) to transmit power. The clutch controls the driven plate, which moves forward and backward to compress and release the clutch friction plate to cut off and engage the power.

The function of the pressure plate and driven plate of the automobile clutch is to transmit the engine's power to the gearbox when the two are combined, that is, to transmit power. Friction plate is also called clutch plate because in the clutch, it is combined or clutched through friction clutch, and it is an important part of the clutch.The clutch has three important functions: transmitting power; cutting off power; and preventing overloading.

Auto parts are the basis for the development of the automobile industry and an important part of the automobile industry. The development of the auto parts industry relies on the development of complete automobiles. In turn, the development of the auto parts industry will also promote and promote the development of complete automobiles. Therefore, the automobile clutch industry is one of the important sub-industries of the automobile parts industry, and its development also relies on the development of the automobile industry.

As a professional R&D and manufacturing base for automobile clutches and peripheral accessories, Lihong produces its core raw materials and molds independently, forming an integration of upstream and downstream supply chains. More than 70% of Lihong's products are exported to Europe, America, and Africa. More than 80 countries and regions including Asia, including OEM production for international first-line brands.