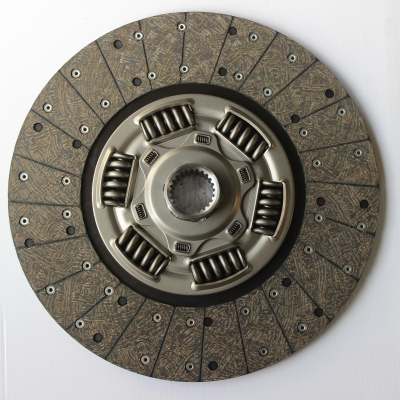

Composite Yarn Clutch Facing Material LH018-2

Features:

1. High strength: Composite yarn clutch facings are made of a combination of different fibers, such as aramid, carbon, or synthetic fibers. These fibers provide high strength and durability to the clutch facing, making it resistant to wear and tear.

2. Good heat resistance: The materials used in composite yarn clutch facings have excellent heat resistance properties, allowing them to withstand high temperatures without softening or degrading. This ensures consistent performance even under extreme operating conditions.

3. Low wear rate: The combination of different fibers in composite yarn clutch facings results in a low wear rate. This means that they have a longer lifespan and require less frequent replacement compared to traditional clutch facings.

4. Stable friction performance: Composite yarn clutch facings provide stable friction performance, ensuring smooth and reliable clutch engagement. They offer excellent torque transmission and minimize slipping or stuttering during clutch engagement.

5. Reduced noise and vibration: The structure of composite yarn clutch facings helps dampen noise and reduce vibration during clutch operation, resulting in improved driving comfort.

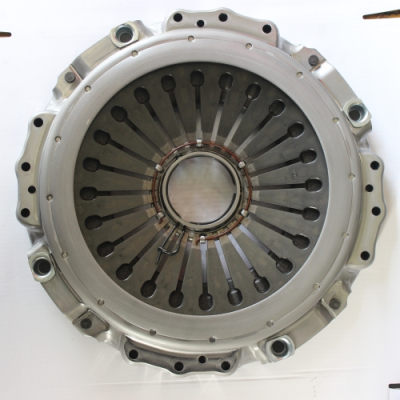

Product description

Composite yarn clutch facings are clutch facings that are made of composite yarn materials. Composite yarn clutch facings are often considered more environmentally friendly compared to traditional asbestos-based clutch facings. They do not contain hazardous materials and have low toxicity, making them safer to use and dispose of. Overall, composite yarn clutch facings offer excellent performance, durability, and reliability, making them suitable for a wide range of applications in automotive and industrial machinery.

Product parameters

Product Properties | |||

Warranty | 12 Months | Place of Origin | Shandong, China |

Size | 430mm*240mm*3.6mm | Type | Clutch facing |

Brand Name | LH | Car Model | all models |

Condition | New | Product name | clutch facing |

Certification | TS16949 | Material | Non-Asbestos Copper Composite yarn |

Min Diamete | 140 mm | Max Diamete | 430 mm |

Thickness | 3mm-5mm | Application | All Models |

MOQ | 100 PCS | Weight | 0.7 kg |

Packing | Carton | Payment | T/T |

Quality | 100% Tested | Port | Qingdao Port |

General Standard for Non-Asbestos Clutch Facings | |||

Product name | Clutch facing | Density | 2.00±0.1g/cm² |

Hardness | HRL40-90 | Delivery Detail | 30 DAYS FOR 20 FEET CONTAINER |

Bending strength | ≥50 (N/mm2) | Packaging Detail | PVC bag packed and Carton Can |

Maximum strain | ≥15 (10-3mm/mm) | Rotary burst strength(200×130) | Normal Temp ≥12000R/Min; |

Specifications | Clutch Facing with glass fiber and cooper wire as backbone, | ||

Packaging and shipping

Product application

Composite yarn clutch face is mainly used in clutch systems of mechanical equipment, automobiles and motorcycles. Its applications include the following:

1. Automobile clutch: Composite yarn clutch face is widely used in automobile clutch system. They provide efficient frictional performance, ensuring stable clutch operation and reliable power transmission.

2. Industrial machinery: Composite yarn clutch face is suitable for clutch systems in various industrial machinery and equipment. They are capable of withstanding high torques and loads, and provide consistent clutch performance and durability.

3. Motorcycle clutches: Composite yarn clutch facings are also commonly found in motorcycle clutch systems. Motorcycle clutches face increased friction and wear, and composite yarn clutch facings provide the durability and reliable clutch performance required.

Inventory