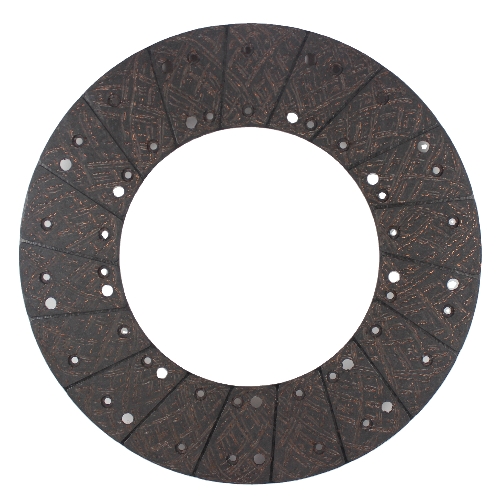

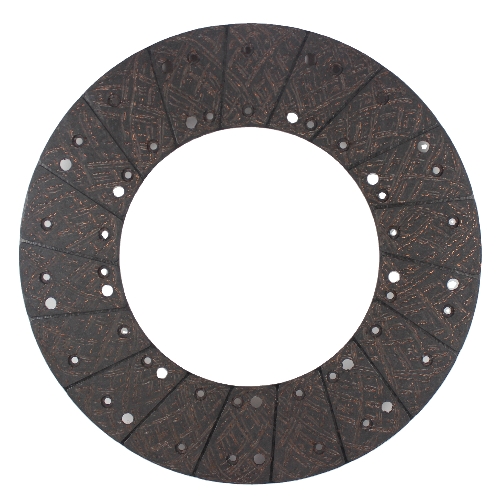

High Copper Clutch Facing LH8106

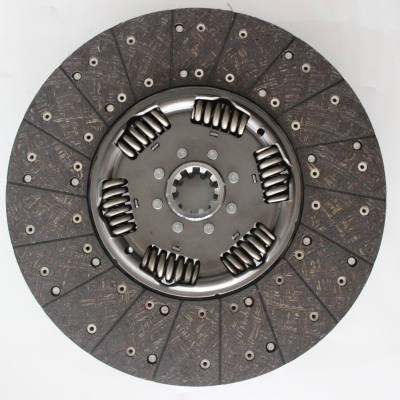

The clutch is an important part of the automobile transmission system, which is used to control the connection and separation between the engine and the transmission. By increasing the number of friction plates and steel plates, the clutch can withstand greater torque, the material selection and structural design of the clutch make it able to work under high temperature conditions, because of the design of friction plates and steel plates, the life of the clutch is usually longer than other types of clutches, widely used in all kinds of cars, motorcycles and construction machinery and other vehicles. Especially the traditional manual transmission system.

Product description

The main material of High Copper Clutch Facing LH8106 is composite cloth made of ordinary medium alkali (non-alkali) glass fiber mixed fiber and 4-7 0.19 copper wire, imported styrene butadiene rubber 1502, high decomposition temperature phenolic resin, friction performance regulator, etc. High Copper Clutch Facing LH8106 using the traditional rubber immersion process production; Due to the high copper wire content, it significantly improves the mechanical strength and wear resistance of the product, which is suitable for all kinds of trucks, especially heavy trucks, and can greatly improve the service life of the clutch.

The Main Performance Index

1.Density:2.00±0.1g/cm2

2.Hardness:HRL40-100

3.Bending strength≥50(N/mm2),Maximum strain≥10(10-3mm/mm).

4.Friction and wear properties meet the demand of below table:

Temperature。C | 100 | 150 | 200 | 250 | 300 | More100 |

Friction Coefficient(μ) | 0.45±0.07 | 0.45±0.08 | 0.45±0.09 | 0.45±0.10 | 0.45±0.11 | 0.45±0.07 |

Wear Rate (ν)10-7cm3/(N·m) | ≤0.15 | ≤0.20 | ≤0.25 | ≤0.28 | ≤0.32 | / |

Packaging and shipping

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.