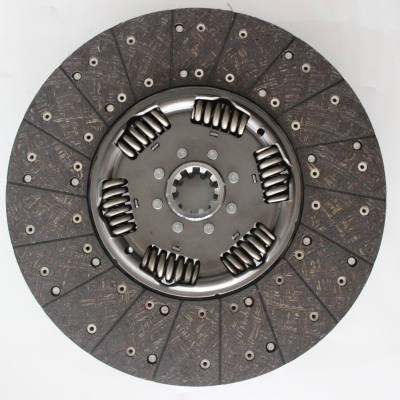

Twin Disk Clutch for XCMG

Highlight 1: The self-developed carbon fiber surface is specially designed for wide-body vehicles, which is stable and strong.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 6: Thickened back cover with countersunk holes, more firm riveting.

Product Details

The driven plate assembly is composed of friction plates, driven plate hubs and other parts, and is used to transmit engine power to the driven parts of the transmission. The car clutch driven plate is another component of the clutch. Clutch driven discs can be widely used in automobiles. Mechanical equipment such as motorcycles and generator sets can control the start, stop, operation, gear shifting, etc. of the engine to ensure the safe operation of the mechanical equipment.

Advantages of disc clutch

1. Reduce engine loss: The clutch driven disc reduces engine loss and reduces engine loss when the engine speed changes. This improves the engine's fuel efficiency.

2. Energy saving and environmental protection: The clutch driven plate can improve engine fuel efficiency. This reduces the vehicle's fuel consumption and emissions. To achieve the purpose of energy saving and environmental protection.

3. Low noise: The clutch transmission plate can control the engine speed. This reduces engine noise and allows the vehicle to run quieter.

Product testing equipment

Failure example

Phenomenon: The car clutch makes abnormal noise when disengaging or engaging.

Reasons: The release bearing lubricating oil is missing, causing dry friction or bearing damage; there is no gap between the bearing and the inner end of the release rod; there is serious oil and dust between the release bearing sleeve and the guide tube, or the release bearing return spring and pedal return spring are fatigued and broken , falling off, causing the release bearing to return poorly; the spline hole of the driven plate and its spline shaft cooperate to lift; the damping spring of the driven plate is fatigued or broken due to annealing; the rivet of the driven plate friction plate is lifted or the rivet is lifted or the rivet head is exposed; The transmission pin of the double-plate clutch and the pin holes of the intermediate pressure plate and pressure plate are worn and hollow.

Diagnosis and troubleshooting: Depress the clutch pedal gently to make the release bearing contact the release rod. If there is a "rustling" noise, it means the bearing is noisy. If there is still noise after refueling, the bearing is excessively worn and damaged and should be replaced. Depress and lift the clutch pedal. If there is intermittent collision sound, it means that the release bearing moves forward and backward, and the release bearing return spring should be replaced; depress the pedal. If there is noise when the clutch is just engaged or disengaged, it means that the rivets of the driven plate are lifted or exposed, and the driven plate should be replaced.

Company's strengths

As a professional R&D and production base for automobile clutches and peripheral accessories, Leehom has the advantage of unique core raw materials and core technology. and the product quality is manageable and stable. It is a company with a complete industrial chain operating model both domestically and abroad. Forming a complete industry chain, more than 70% of Leehom's products are exported to more than 80 countries and regions in Europe, America, Africa and Asia.

Our services

1. Welcome OEM production: products, packaging...

2. Order samples

3. We will answer your questions within 24 hours.

4. After shipping, we will track the goods every 2 days until you receive the goods. When you receive the product Please test and give us your feedback. If you have any questions about this problem Please contact us. We will give you a solution.