Clutch Cover Plate For XCMG

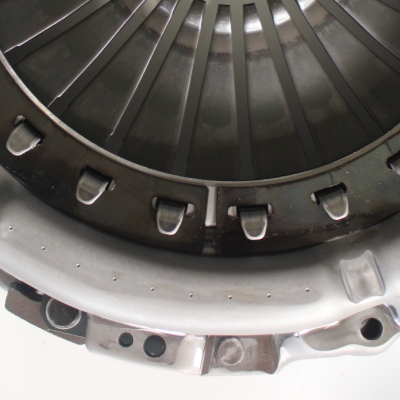

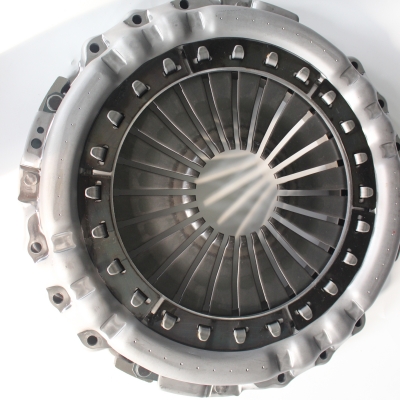

Highlight 1: Using 7mm cold-rolled plate, the appearance is clean and the thickness of the material ensures the strength of the cover without deformation under high pressure.

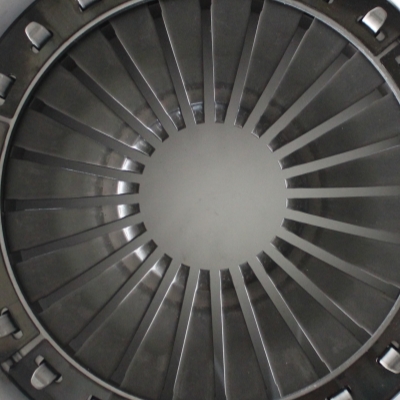

Highlight 2: The diaphragm rock spring is made of 50CrV4 high elastic spring steel. The material is suitable for high-horsepower vehicles. After professional heat treatment, it produces strong torque transmission and stable high pressure.

Highlight three: The bottom of the plate is made of HT250 cast iron. Its hardness and tensile strength are more suitable for friction and torque transmission needs. Its weight fully meets the heat capacity and inertia requirements, reducing ablation and frustration.

Product details

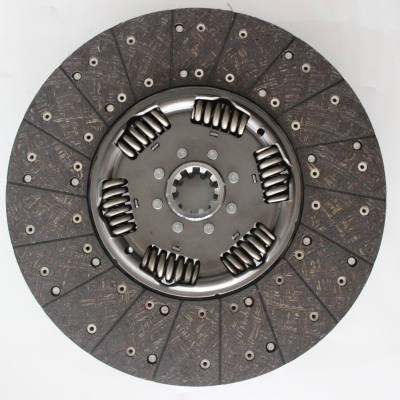

The clutch pressure plate is one of the most important components of the clutch assembly. And the function of the clutch plate plays an important role in vehicle driving safety. Depending on the driver's needs, engine power is transmitted or disconnected via mechanical linkages. The car starts smoothly in conjunction with the clutch plate. Smooth gear changes Prevents the engine from overworking Spring friction clutches (friction clutches for short) are widely used in clutch disc brakes. The torque generated by the engine is transmitted to the driven plate through friction between the flywheel, pressure plate, and driven plate. When the driver depresses the clutch he pushes the diaphragm backwards through the big end of his spring pressures his plate through the mechanical parts. At this time, the driving part is separated from the active part.

Advantages of clutch pressure plate

Pressure Support: The clutch pressure plate supports the pressure of the clutch pressure plate spring. It is passed between the clutch plate and the flywheel to ensure the normal operation of the clutch.

Metal material: High strength metal materials such as steel and aluminum alloy are usually used for clutch pressure plates. This ensures sufficient strength and durability.

Friction Surface: Clutch pressure plates usually have a friction surface. Its role is to contact the clutch plate and provide friction so that the clutch plate can properly contact and disengage the flywheel.

Adjustment Mechanism: Some clutch pressure plates have an adjustment mechanism to adjust the clearance between the clutch plate and the flywheel. Adjusting this gap will ensure proper clutch operation. Includes smooth clutching and disengagement.

Structural design: The structural design of the clutch pressure plate can be adjusted to suit different vehicles and applications. For example, some vehicles use dual-plate clutch pressure plates to improve load-bearing capacity and efficiency.

Packaging and shipping

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.