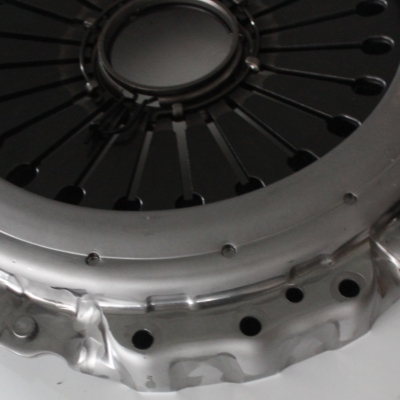

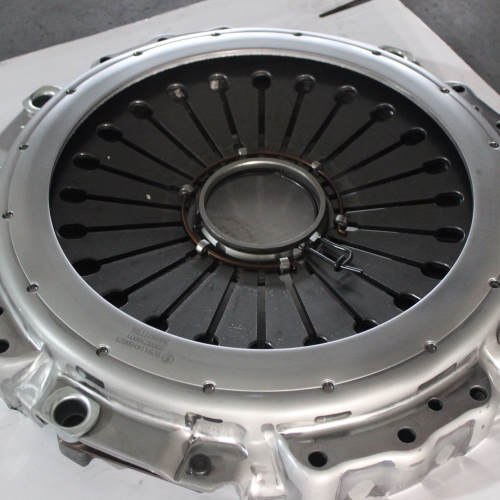

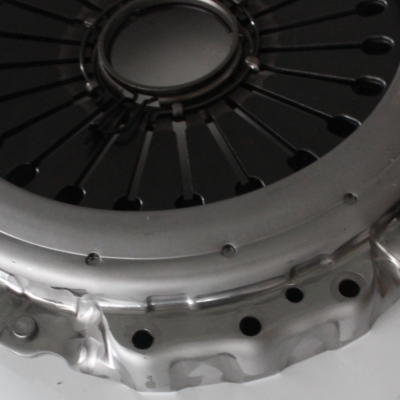

Clutch Cover Plate For Mining Truck

Highlight 1: Using 7mm cold-rolled plate, the appearance is clean and the thickness of the material ensures the strength of the cover without deformation under high pressure.

Highlight 2 The bottom of the plate is made of HT250 cast iron. Its hardness and tensile strength are more suitable for friction and torque transmission needs. Its weight fully meets the heat capacity and inertia requirements, reducing ablation and frustration.

Highlight 3: Separate pull ring stamping forming, carbonitriding ensures tensile toughness and wear resistance

Highlight 4: The limit snap ring reduces the risk of failure caused by bumping and deformation during transportation, and also facilitates installation.

Product description

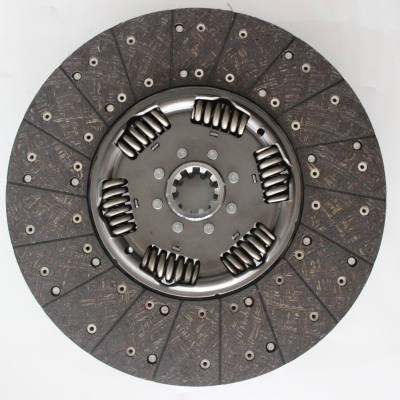

The clutch pressure plate is an important structure of the clutch. And the function of the clutch plate plays an important role in vehicle driving safety. The clutch pressure plate is one of the most important components of the clutch assembly, transmitting or decoupling engine power through a coupling mechanism depending on the driver's needs. It works in conjunction with the clutch plate to make the car start smoothly. Smooth gear changes prevent engine overload

Pressure Support: The clutch pressure plate receives pressure from the clutch pressure plate spring and transmits it between the clutch plate and the flywheel to ensure the normal operation of the clutch.

Metal material: High strength metal materials such as steel and aluminum alloy are usually used for clutch pressure plates. This ensures sufficient strength and durability.

Friction Surface: Clutch pressure plates usually have a friction surface. Its role is to contact the clutch plate and provide friction so that the clutch plate can properly contact and disengage the flywheel.

Adjustment Mechanism: Some clutch pressure plates have an adjustment mechanism to adjust the clearance between the clutch plate and the flywheel. By adjusting this gap, reliable clutch operation is possible. Includes smooth clutching and disengagement.

Structural design: The structural design of the clutch pressure plate can be adjusted to suit different vehicles and applications. For example, some vehicles use double-disc clutch pressure plates to improve load-bearing capacity and efficiency.

Application

1. Car: The clutch pressure plate is an important part of the traditional manual transmission system. It connects the gear input shaft to the engine flywheel. The transmission and clutch are controlled by adjusting the pressure between the clutch plates and flywheel.

2. Motorcycle: The clutch system of motorcycles generally uses a combination of clutch pressure plate and clutch plate. The clutch pressure plate senses clutch and disengagement through contact between the clutch plates and the engine flywheel. and control power transmission

3. Engineering machinery: Clutch pressure plates are also widely used in construction machinery and equipment such as excavators, bulldozers, and cranes. The clutch pressure plates play the same role in these equipment as the clutches in cars or motorcycles. It controls the transmission of electricity and the operation of equipment.

4. Agricultural machinery: agricultural tractors and other agricultural machinery. Clutch pressure plates are commonly used in clutch and release transmission systems. The clutch system improves control and maneuverability. This gives operators greater control over the operation of farm equipment and power systems.

Packaging and shipping