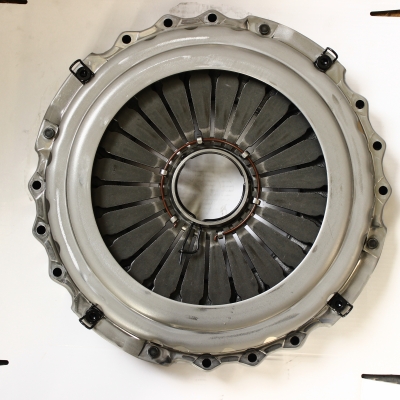

Clutch Cover For Tipper Truck

Withstand Pressure: The clutch pressure plate takes the strain from the grab strain plate spring and transmits it between the snatch disc and flywheel to make certain the ideal operation of the clutch.

Metal Material: Clutch pressure plate is normally made of excessive energy metallic material, such as metal or aluminum alloy, to make sure enough energy and durability.

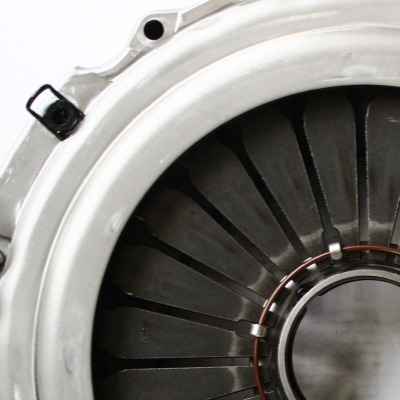

Friction surface: The clutch stress plate typically has a friction floor that serves to make contact with the snatch disc to grant friction so that the take hold of disc can good contact and disengage from the flywheel.

Adjustment Mechanism: Some clutch pressure plates are outfitted with an adjustment mechanism to regulate the hole between the grab disc and the flywheel. By adjusting this gap, it ensures suitable snatch operation and easy clutching and disengagement.

Product description

The friction clutch pressed by a spring (friction clutch for short) is widely used for clutch pressure plate braking. The torque generated by the engine is transmitted to the driven plate through the friction between the flywheel and the contact surface between the pressure plate and the driven plate. When the driver depresses the clutch pedal, the big end of the diaphragm spring drives the pressure plate to move backward through the transmission of the mechanical parts. At this time, the driven part is separated from the active part.

There is a friction plate on the clutch pressure plate, just like the brake pad on the wheel. It is made of very wear-resistant asbestos and copper wire. The friction plate on the pressure plate also has a minimum allowable thickness. After driving for a long time, the friction plate on the pressure plate will The friction plates also need to be replaced.

Application

Automobiles: The Clutch Cover is an necessary element in typical guide transmissions. It is linked to the enter shaft of the transmission and the flywheel of the engine to manage energy transmission and clutching by using adjusting the strain between the grasp disc and the flywheel.

Motorcycle: The Clutch Cover of a bike generally makes use of a aggregate of a grab strain plate and a take hold of disc. The snatch stress plate realizes clutching and disengaging thru the contact between the snatch plate and the flywheel of the engine to manage the electricity transmission.

Construction Machinery: Clutch strain plate is additionally broadly used in development equipment and equipment, such as excavators, bulldozers, cranes and so on. The seize stress plate performs a comparable function to car and bike clutches in these equipments, controlling electricity transmission and operation of the equipments.

Agricultural Machinery: Farm tractors and different agricultural equipment additionally commonly use grab stress plates to snatch and disengage the pressure system. Clutch structures grant higher manage and ease of operation, permitting the operator to higher manage the operation and strength output of the farm machinery.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible