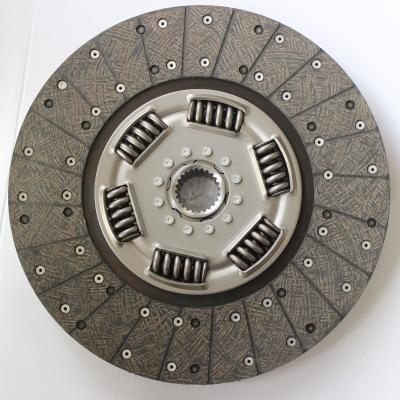

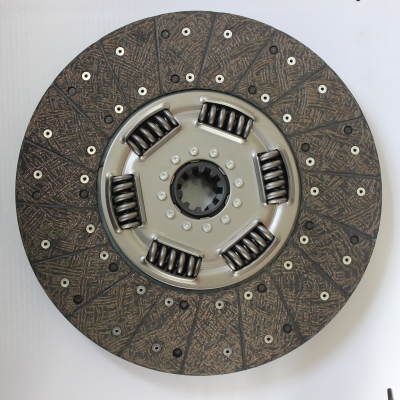

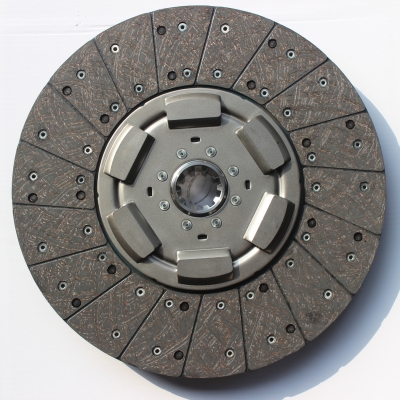

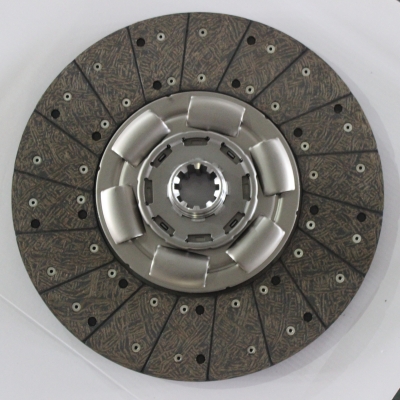

Clutch Disc For XKT136 XCMG

Highlight 1: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 2: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 3: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 4: 55 chrome silicon springs are used to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 5: The back cover is laser welded, which is not easy to crack

Highlight 6: Adopt self-developed surface, specially designed for heavy-duty vehicles.

Product description

The clutch plate is an important part of the clutch. It is a round steel plate. These are usually made of friction material that is attached to the engine's crankshaft. The purpose of the mounting plate is to transfer engine power to the gearbox. When releasing the clamp, the mounting plates stick together due to friction and rotate together. In this way, the power from the engine is transferred through the pressure plate to the transmission, propelling the vehicle forward. When depressing the clutch, he can decouple the engine and transmission by limiting or eliminating friction between the clutch pressure plate and the catch plate to separate them. Energy is no longer transferred. You can stop your car and change cars

1. Clutch structure: A clutch mainly consists of a control part, transmission part, contacts, and friction plates. These work together to make the clutch work efficiently.

2. Working principle: The clutch connects the transmission part and the contact points by controlling the movement of the controller. Therefore, the power from the engine is sent to the transmission system. He can also close the clutch and shift gears with the transmission when the engine reaches the position set by the controller.

3. Role of friction plate: The friction plate in a clutch plays the role of controlling and maintaining stability. It can effectively reduce the sliding friction and extend the life of the clutch.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

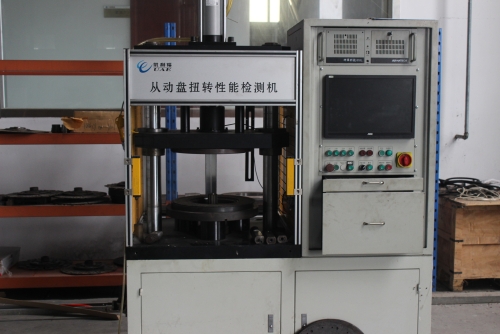

Testing Equipment

Packaging and shipping

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

Company strength

Shandong Litong Clutch Manufacturing Co., Ltd. was founded in 2011. The company is located at No. 168, Chengnan High-tech Development Zone, Yanggu County, covering an area of 60,000 square meters and currently has more than 200 employees. It is a professional company integrating scientific research and development, production and manufacturing, and sales services. Automobile clutch assembly manufacturer.

Shandong Litong will always adhere to the business philosophy of "pursuit of excellence, integrity first", relying on advanced management models, scientific quality systems, strong technical force, and complete testing equipment to effectively ensure the stability and reliability of product quality. Provide first-class products to new and old users at home and abroad, and jointly create a better tomorrow!

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible