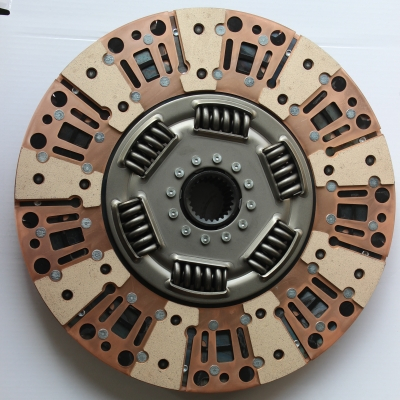

Clutch Disk For Mining Truck

Highlight 1: The self-developed carbon fiber surface is specially designed for wide-body vehicles, which is stable and strong.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 6: Thickened back cover with countersunk holes, more firm riveting.

Product description

The clutch is a component in the automobile's transmission system that is directly connected to the engine. Its function is to enable the active and driven parts to be completely separated under the driver's control, and then rejoined softly. Under the pressure of the compression spring, the engagement tightness between the clutch driven plate assembly and the flywheel continues to increase, that is, the rotation speeds of the two tend to be equal, and the torque transmitted from the engine to the drive wheels through the transmission system gradually increases until the traction force is sufficient When the starting resistance is overcome, the car starts moving from a standstill and gradually accelerates.

The technical solution adopted by Clutch Disk For Mining Dump Truck is a clutch driven plate assembly, including a first friction lining, a driven plate steel plate, a driven plate hub, a shock absorber plate and a second friction lining arranged in sequence. There are 4 corresponding windows evenly arranged on the circumference of the driven disc steel sheet, driven disc hub and shock absorber disc, and are connected by damping springs.

How to maintain and maintain a car clutch

Friction is used to transmit power between the master and slave plates. Therefore, in actual operation, there is a concept of "semi-linkage", that is, the rotation speeds between the two are not exactly the same, and only part of the power is transmitted. At this time, the driven plate wears the most. Minimizing the wear in this process can extend the service life of the clutch.

Product parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

Packaging and shipping

Company strength

Lihong Holding Group Co., Ltd. was founded in 1978 and is a professional group company integrating research and development, production, sales service. and international trade for high-end composite materials. clutch friction plate and clutch assembly In order to strictly control product quality, Lihong has launched the latest testing equipment and strictly complies with the national standard ISO/TS16949 quality system requirements. The product quality fully complies with the QC/T25-2004 industry standard, and we have established an international advanced testing system product testing center.