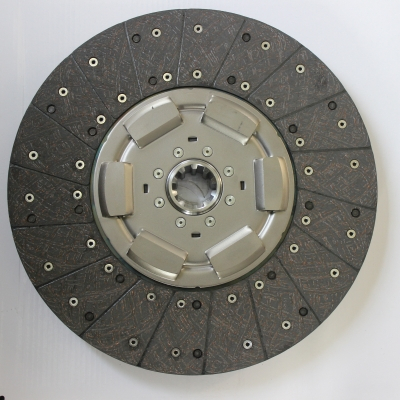

Glass Fiber Clutch Facing LH209

Glass fiber clutch facing has the following characteristics:

1. High Strength: Fiberglass is a high-strength material, which makes the fiberglass clutch face have excellent load-bearing capacity and wear resistance.

2. Heat resistance: Glass fiber has good high temperature resistance, can maintain stable performance in high temperature environment, and is not easy to soften or melt.

3. Lightweight: Compared to metal materials, fiberglass clutch facings have a lower density and are therefore lighter in weight, helping to reduce the weight of the entire clutch system.

4. Corrosion resistance: The glass fiber clutch face has good corrosion resistance to acids, alkalis, corrosive gases, etc., and can operate in harsh environments for a long time.

5. Good friction characteristics: The surface structure of the glass fiber clutch face is uniform and has excellent friction characteristics, which can provide good transmission effect and stable performance.

6. Long Life: Due to the high strength and abrasion resistance of the fiberglass clutch face, it has a long service life and is not easily damaged or worn.

Product description

Depending on the application, clutch facings can be made from a variety of materials, but some of the most common include asbestos, textile fabrics such as Kevlar and Kevlar, and ceramic materials. Like disc brake pads and other clutch materials, the materials used for clutch facings need to be durable. Because the process of driveshaft engagement and disengagement involves the conversion of kinetic energy to thermal energy, the clutch facings must be able to withstand the tension and high temperatures reached during this process. Clutch facings are used in marine engines, heavy truck and light vehicle engines, power presses, friction pads, and many industrial applications. The smooth and consistent performance of many engines can be attributed to the presence of high quality clutch facings.

Product parameters

Product Properties | |||

Warr anty | 12 Months | Place of Origin | Shandong, China |

Size | 430mm*240mm*3.6mm | Type | Clutch facing |

Brand Name | LH | Car Model | all models |

Cond ition | New | Product name | clutch facing |

Certifi cation | TS16949 | Material | Glass fiber |

Min Dia mete | 140 mm | Max Diamete | 430 mm |

Thickn ess | 3mm-5mm | Application | All Models |

MOQ | 100 PCS | Weight | 0.7 kg |

Packing | Carton | Payment | T/T |

Quality | 100% Tested | Port | Qingdao Port |

General Standard for High Copper Clutch Facings | |||

Product name | Clutch facing | Density | 2.00±0.1g/cm² |

Hard ness | HRL40-90 | Delivery Detail | 30 DAYS FOR 20 FEET CONTAINER |

Bend ing strength | ≥50 (N/mm2) | Packaging Detail | PVC bag packed and carton can print brand name or logo onto the facing. |

Maximu m strain | ≥15 (10-3mm/mm) | Rotary burst strength (200×130) | Normal Temp ≥12000R/Min; 200ºC≥10000R/Min |

Specific ations | Clutch facing with glass fiber and cooper wire as backbone, temperature-reistance resin, high temperature endurance. | ||

Packaging and shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company strength

Founded in 1978, Leehom Holdings Group Co., Ltd. is a professional group company integrating R&D, production, sales services and international trade of high-end composite materials, clutch friction plates, and clutch assemblies. It has five subsidiaries (Shandong Waterfall Composite Materials Co., Ltd., Yanggu County Rainbow Auto Parts Co., Ltd., Shandong Litong Clutch Manufacturing Co., Ltd., CITIC Jinan Clutch Manufacturing Co., Ltd., and Shandong Knight International Trading Co., Ltd.). Co., Ltd.) Co., Ltd. is one of the enterprises with the greatest development potential in the global clutch industry by virtue of its advantages in scientific research and development, production, sales and service support.

FAQ

Q1. What are the packaging conditions?

A: Usually, products are packed in neutral white boxes and brown cartons. If you have a legally registered patent,After receiving the approval letter, we will package the products in branded boxes.

Q2. What are the payment terms?

A: 30% as T/T deposit, 70% before delivery. Photos introducing products and packaging before paying the balance.

Q3. What are the delivery terms?

A: EXW, FOB, CFR, CIF.

Q4. How about the delivery time?

A: Generally, it will take 30 days after receiving the advance payment. The specific delivery date depends on the situation Regarding the products and quantities of your order.

Q5. Can you produce according to samples?

A: Yes, we can produce according to samples or technical drawings. We also manufacture molds and jigs.

Q6. What is the insurance sample?

A: We can provide samples if we have ready parts in stock.

Q7. Do you test all goods before delivery?

A: Yes, we have 100% test before delivery.

Q8: How do you make our business long-term and good relationship?

Answer: 1. We maintain good quality and competitive price to ensure our customers benefit;

2. We respect every customer, just like our friends, sincerely do business and make friends with them, no matter where they come from.