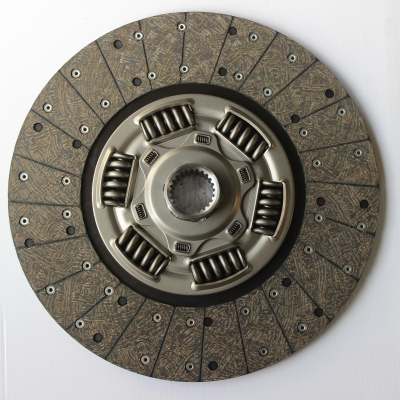

Clutch Driven Disc For Mine Truck

Highlight 1: The self-developed carbon fiber surface is specially designed for wide-body vehicles, which is stable and strong.

Highlight 2: 65m heat-treated steel plate is used, which is durable and heat-set.

Highlight 3: The corrugated plate is bent by laser, and the starting gear is smooth to reduce the clutch damage.

Highlight 4: The splines are tempered in a vacuum furnace to make the pre-shock absorption structure more sensitive and firm, and to solve the idle vibration.

Highlight 5: Using 55 chromium silicon to solve the problems of trembling and broken springs of heavy-duty vehicles.

Highlight 6: Thickened back cover with countersunk holes, more firm riveting.

Product Description

Clutch Driven Disc For Mine Truck uses 65m heat-treated steel plate, which is strong, durable and heat-set. The corrugated plate is laser-bent, allowing for smooth starting and shifting to reduce clutch damage. The splines are quenched and tempered in a vacuum furnace to make the pre-shock absorbing structure more sensitive and firm, eliminating idling vibration. Using 55 chromium silicon to solve the problems of shaking and broken springs in heavy-duty vehicles. The back cover is laser welded and is not easy to crack. It uses a self-developed surface sheet and is specially designed for heavy-duty vehicles.

Product Parameters

OE NO. | 1601210-76A, 1601210-76B | Product Name | |

Warranty | 12 MONTHS | Quality | High-Quality/100% Brand new and High quality |

Place of Origin | Shandong,CHINA | Packing | Carton/ Neutral Packing |

Supply Ability | 1000 Set/Sets per Month | Weight | 15 kg |

Size | 430MM/OEM Standard | Material | Iron and copper |

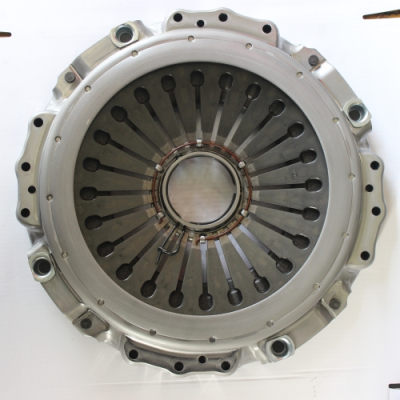

Clutch pressure plate maintenance

The clutch pressure plate is broken, and the clutch feels very hard. Even if the clutch is pressed, it will be uneven, or the driving force is weak, the engine speed will increase, and the vehicle speed will not increase. Nowadays, most clutch pressure plates are integrated with the friction plate, so sometimes problems with the friction plate will also affect the pressure plate. The clutch pressure plate, clutch plate and release bearing are the three-piece set of the clutch. There is no clear regulation on the service life of the pressure plate. However, as an important part of the transmission system, the clutch will have the same service life as the vehicle under normal use, so it is okay to travel more than 100,000 kilometers without any faults. The most important thing is to do regular maintenance and take preventive measures. .

Packaging and shipping

Company strength

Our company is a professional manufacturer of automotive clutch driven plates and pressure plate assemblies and has passed ISO9001 quality management system certification. The surface of the transmission plate is made of high-quality asbestos-free roller plates and asbestos-free roller plates, which have the advantages of wear resistance and high temperature resistance. In addition, we have also developed copper-based friction linings, ceramic steel friction linings, and driven disks, all of which have reached the highest domestic level in quality. The clutch cover and pressure plate castings in the coil spring pressure plate assembly are made of 600-3 spherical cast iron. In the pressure plate assembly, the diaphragm gland spring is made of high-quality deep-drawn steel plate Baosteel SPHE diaphragm spring. The spring leaf is made of high-quality CrMnVA spring steel plate at home and abroad, and is processed by high-frequency quenching. And it has been rigorously tested by the pressure plate assembly comprehensive performance tester before leaving the factory. The internal quality control standard of the clutch assembly is higher than the national standard QC/T25-92, which is stronger, more stable and wear-resistant, and has a long service life.